Difference between revisions of "EM.Picasso"

m (→Visualizing The Far Fields) |

(→Multilayer Green’s Functions) |

||

| Line 13: | Line 13: | ||

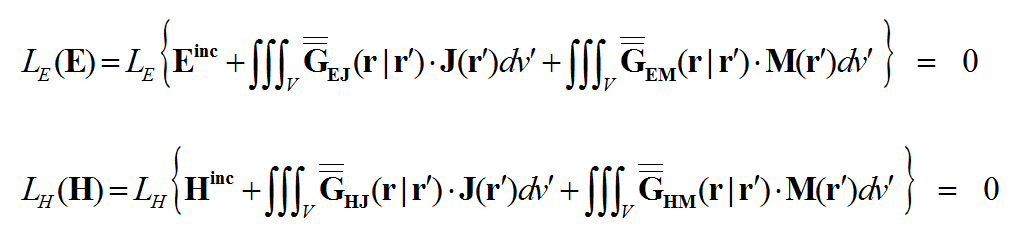

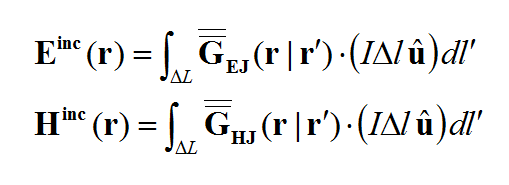

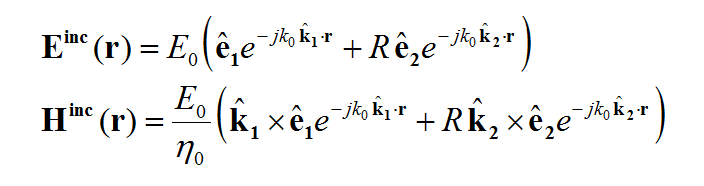

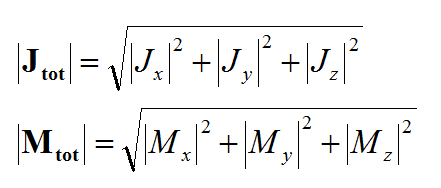

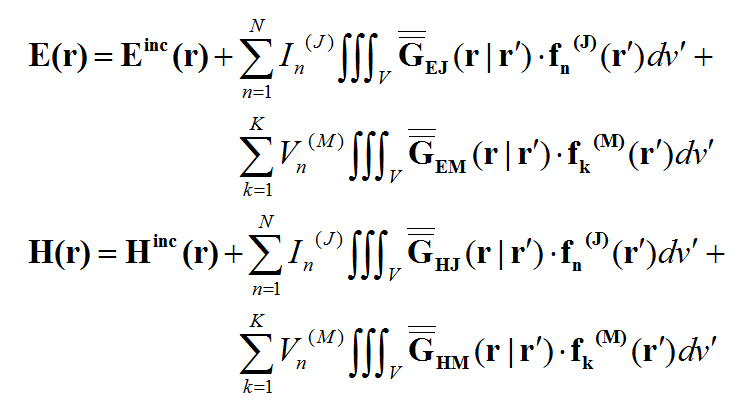

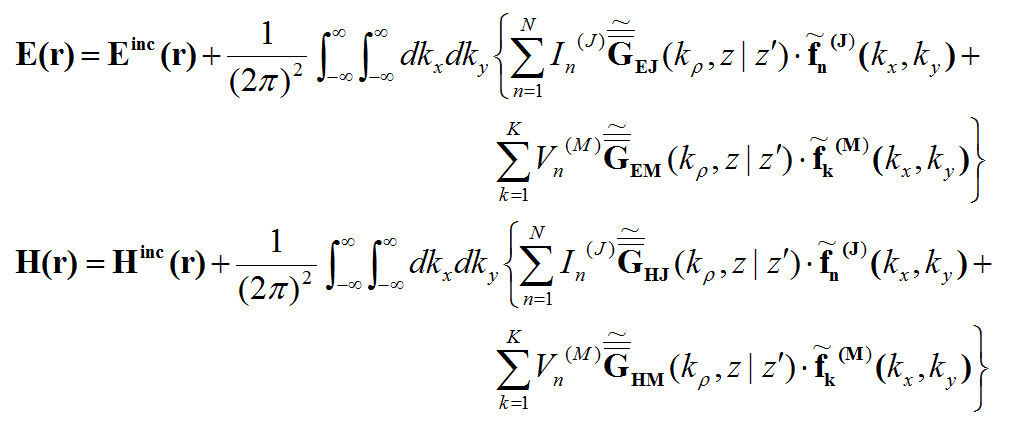

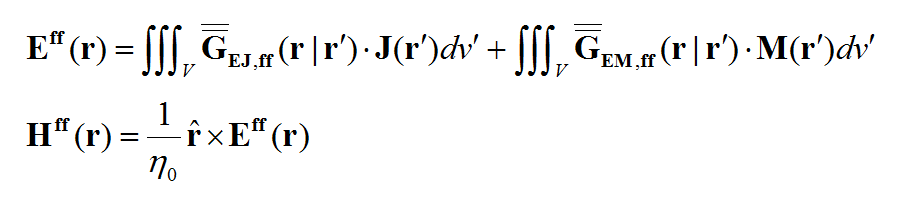

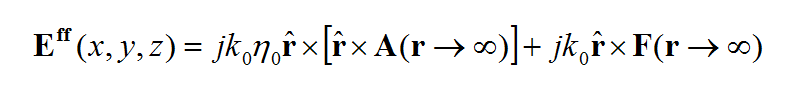

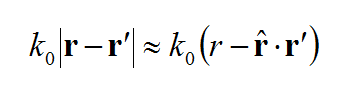

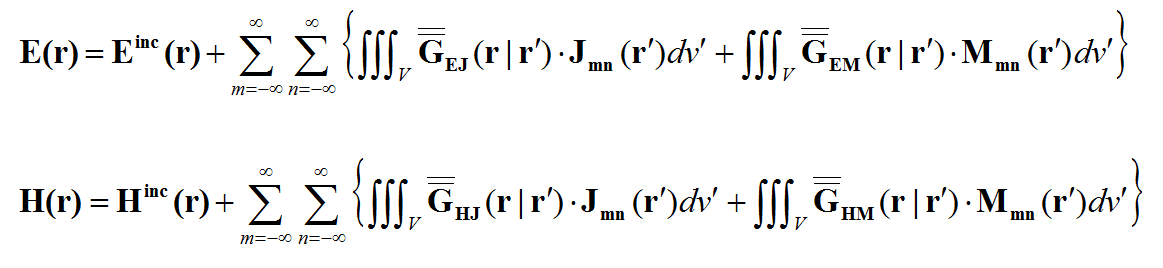

In general, a structure may support both electric ('''J''') and magnetic ('''M''') currents. The total electric ('''E''') and magnetic ('''H''') fields can be expressed in terms of the electric and magnetic currents in the following way: | In general, a structure may support both electric ('''J''') and magnetic ('''M''') currents. The total electric ('''E''') and magnetic ('''H''') fields can be expressed in terms of the electric and magnetic currents in the following way: | ||

| − | + | :<math>E = E^{inc} + \iiint\limits_V \overline{\overline{G_{EJ}}}(r|r') \cdot J(r') \, dv' + \iiint\limits_V \overline{\overline{G_{EM}}}(r|r') \cdot M(r') \, dv'</math> | |

| − | + | :<math>H = H^{inc} + \iiint\limits_V \overline{\overline{G_{HJ}}}(r|r') \cdot J(r') \, dv' + \iiint\limits_V \overline{\overline{G_{HM}}}(r|r') \cdot M(r') \, dv'</math> | |

| + | <!--[[File:PMOM1(1).png]]--> | ||

| + | |||

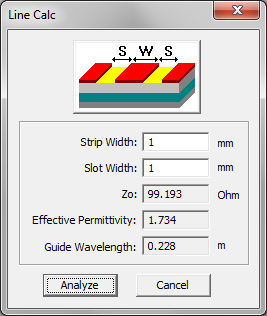

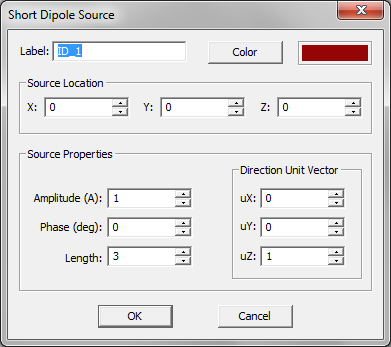

| + | where '''G<sub>EJ</sub>''', '''G<sub>EM</sub>''', '''G<sub>HJ</sub>''', '''GH<sub>M</sub>''' are the dyadic Green’s functions for the electric and magnetic currents due to electric and magnetic current source, respectively, and '''E<sup>i</sup>''' and '''H<sup>i</sup>''' are the incident or impressed electric and magnetic fields, respectively. In these equations, '''r''' is the position vector of the observation point and '''r'''' is the position vector of the source point. V is the volume that contains all the sources and the volume integration is performed with respect to the primed coordinates. The incident or impressed fields provide the excitation of the structure. They may come from an incident plane wave or a gap source on a microstrip line, a short dipole, etc. The complexity of the Green’s functions depends on what is considered as the background structure. If you remove all the unknown currents from the structure, you are left with the background structure. | ||

=== Planar Integral Equations === | === Planar Integral Equations === | ||

| Line 251: | Line 254: | ||

[[File:PMOM26.png]] | [[File:PMOM26.png]] | ||

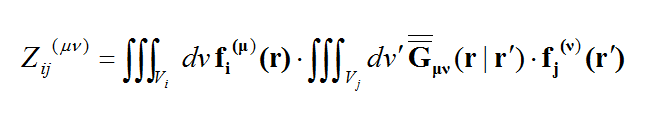

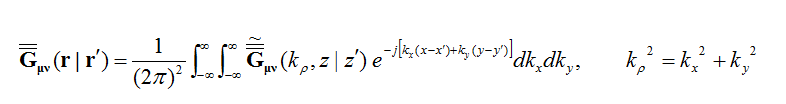

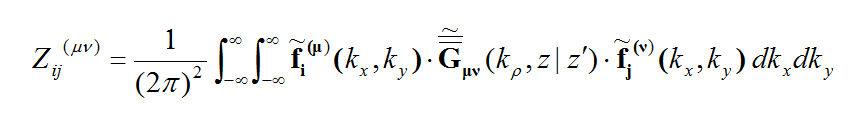

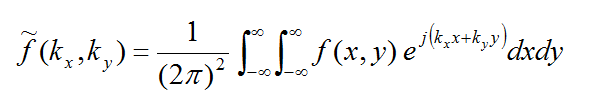

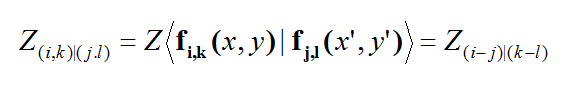

| − | where the doubly infinite integration is performed with respect to the spectral variables k<sub>x</sub> and k<sub>y</sub>. As can be seen from the above expression, the spatial-domain dyadic Green's functions are functions of z, z', as well as (x-x') and (y-y'). The MoM matrix elements can now be transformed into the spectral domain as | + | where the doubly infinite integration is performed with respect to the spectral [[variables]] k<sub>x</sub> and k<sub>y</sub>. As can be seen from the above expression, the spatial-domain dyadic Green's functions are functions of z, z', as well as (x-x') and (y-y'). The MoM matrix elements can now be transformed into the spectral domain as |

[[File:PMOM27.png]] | [[File:PMOM27.png]] | ||

| Line 704: | Line 707: | ||

* R/T Macromodel | * R/T Macromodel | ||

* Huygens Sweep | * Huygens Sweep | ||

| − | * Optimization | + | * [[Optimization]] |

* HDMR | * HDMR | ||

| Line 978: | Line 981: | ||

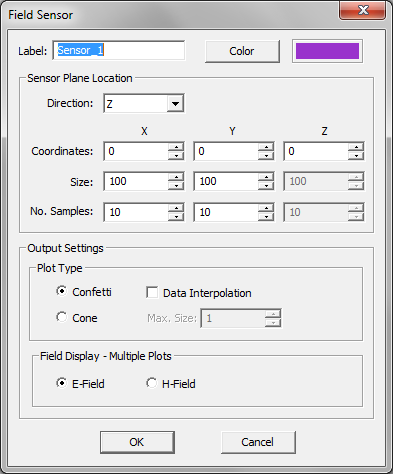

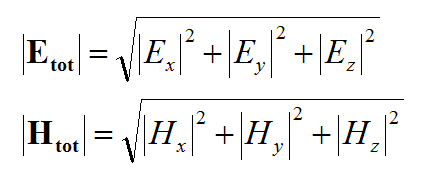

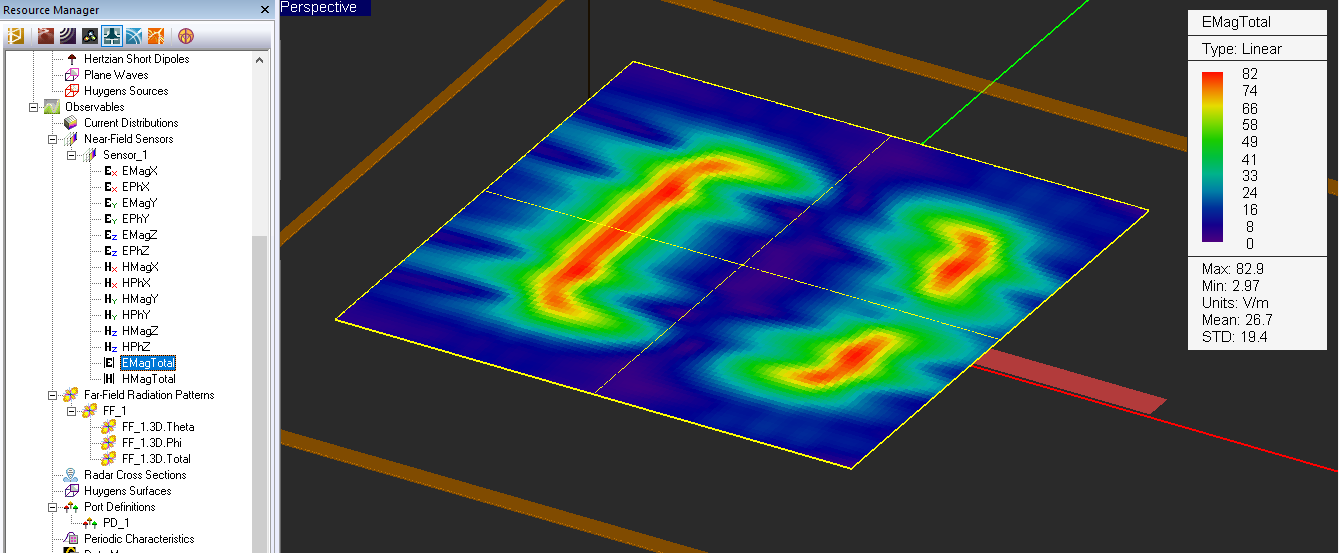

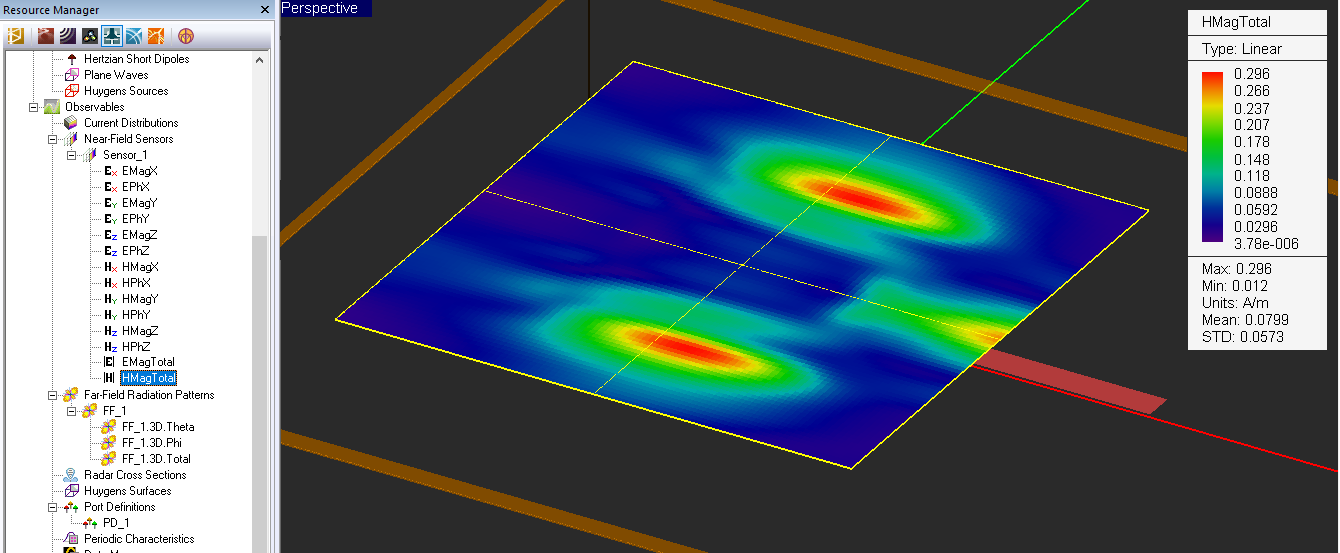

* '''Near-Field Distributions''': Electric and magnetic field amplitude and phase on specified planes and their central axes | * '''Near-Field Distributions''': Electric and magnetic field amplitude and phase on specified planes and their central axes | ||

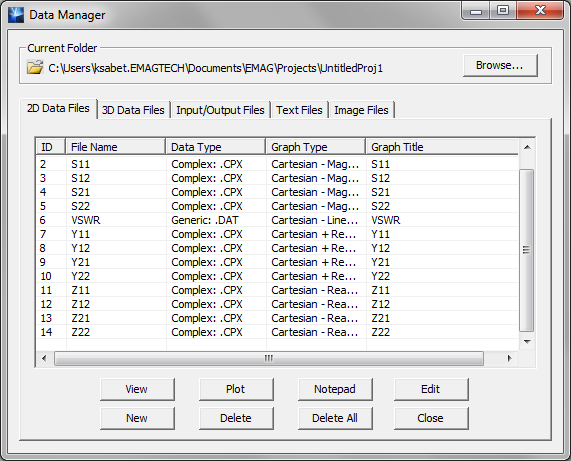

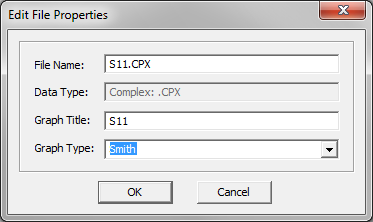

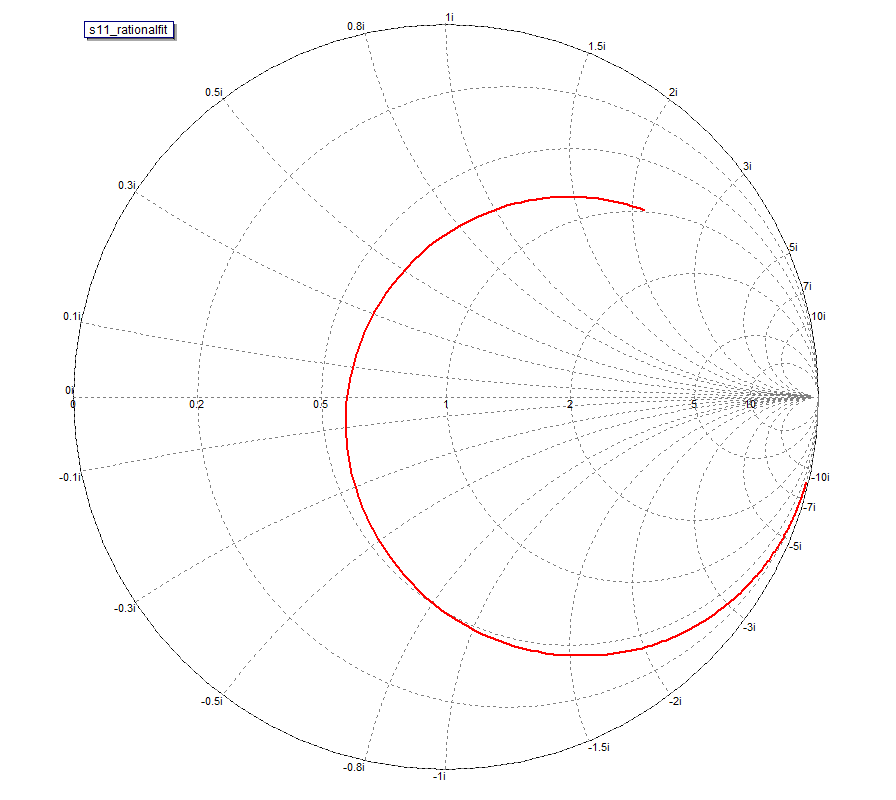

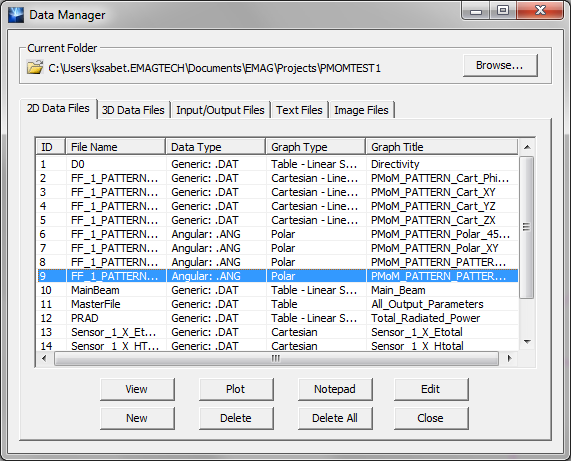

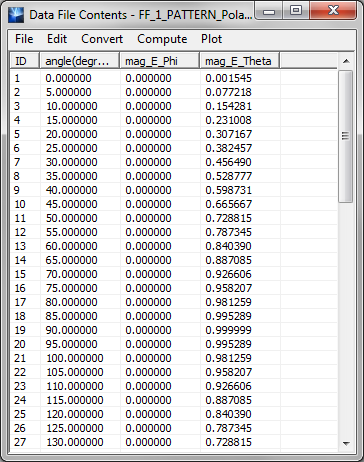

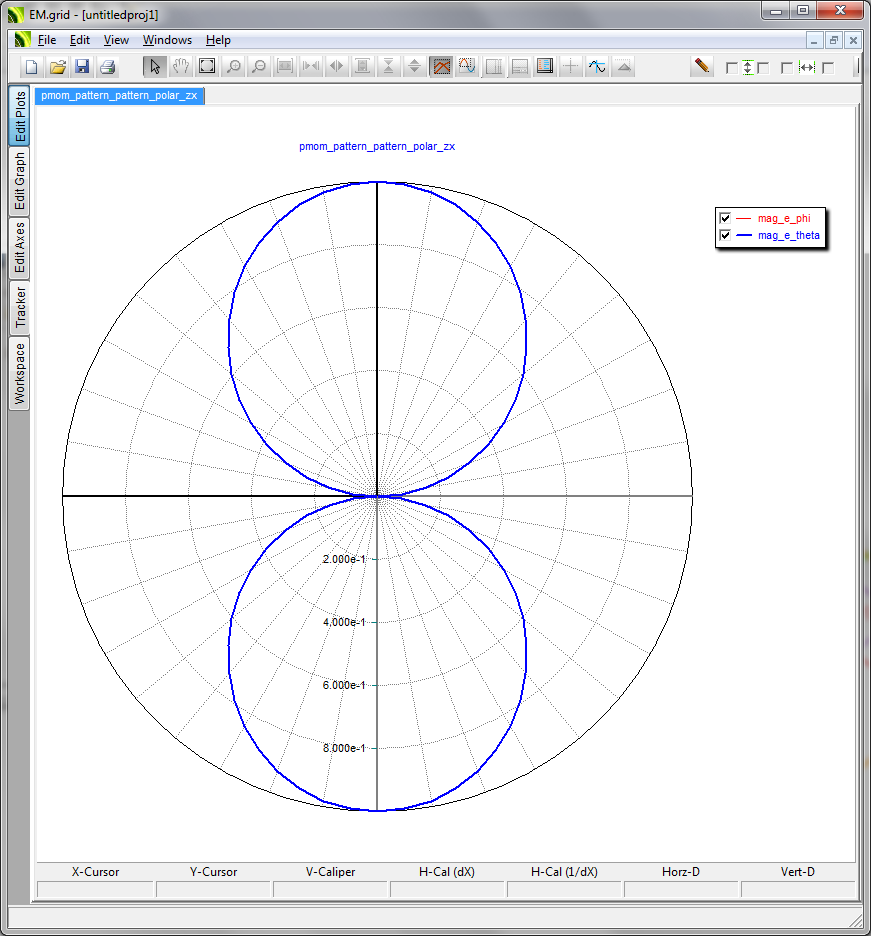

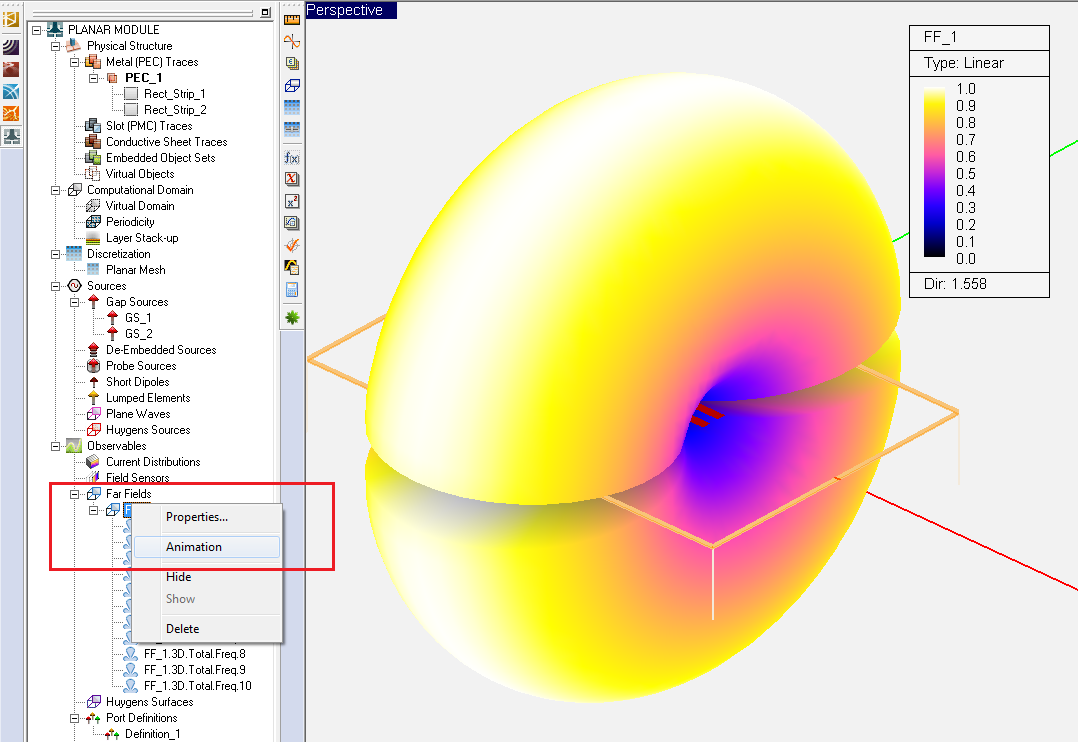

| − | At the end of an analysis, the 2D quantities usually have a single value that is written into an ASCII data file. Complex-valued quantities are written into complex data files with a "'''.CPX'''" extension. Real-valued quantities are written into real data files with a "'''.DAT'''" extension. Polar 2D radiation pattern data and some other radiation characteristics are written into angular data files with a "'''.ANG'''" extension. In this latter file type, polar data are stored as functions of an angle expressed in degrees. At the end of a sweep simulation of one of the many types available (frequency, angular, parametric, etc.), the ASCII output data files are populated with rows that correspond to the samples of the sweep variable(s). If a sweep simulation involves N sweep variables, then the first N columns of the output data files show the samples of those sweep variables. All the 2D data files are listed in the '''2D Data Files''' tab of EM.Cube's '''Data Manager'''. You can view the contents of these data files by selecting their row in the data manager and clicking the '''View''' button of the dialog. | + | At the end of an analysis, the 2D quantities usually have a single value that is written into an ASCII data file. Complex-valued quantities are written into complex data files with a "'''.CPX'''" extension. Real-valued quantities are written into real data files with a "'''.DAT'''" extension. Polar 2D radiation pattern data and some other radiation characteristics are written into angular data files with a "'''.ANG'''" extension. In this latter file type, polar data are stored as functions of an angle expressed in degrees. At the end of a sweep simulation of one of the many types available (frequency, angular, parametric, etc.), the ASCII output data files are populated with rows that correspond to the samples of the sweep variable(s). If a sweep simulation involves N sweep [[variables]], then the first N columns of the output data files show the samples of those sweep [[variables]]. All the 2D data files are listed in the '''2D Data Files''' tab of EM.Cube's '''Data Manager'''. You can view the contents of these data files by selecting their row in the data manager and clicking the '''View''' button of the dialog. |

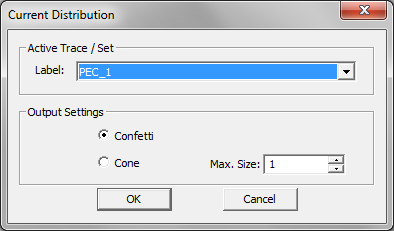

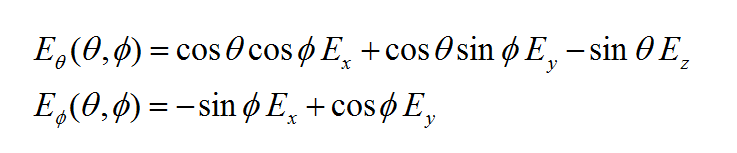

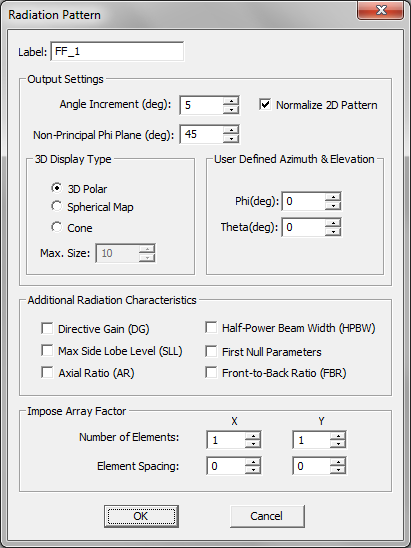

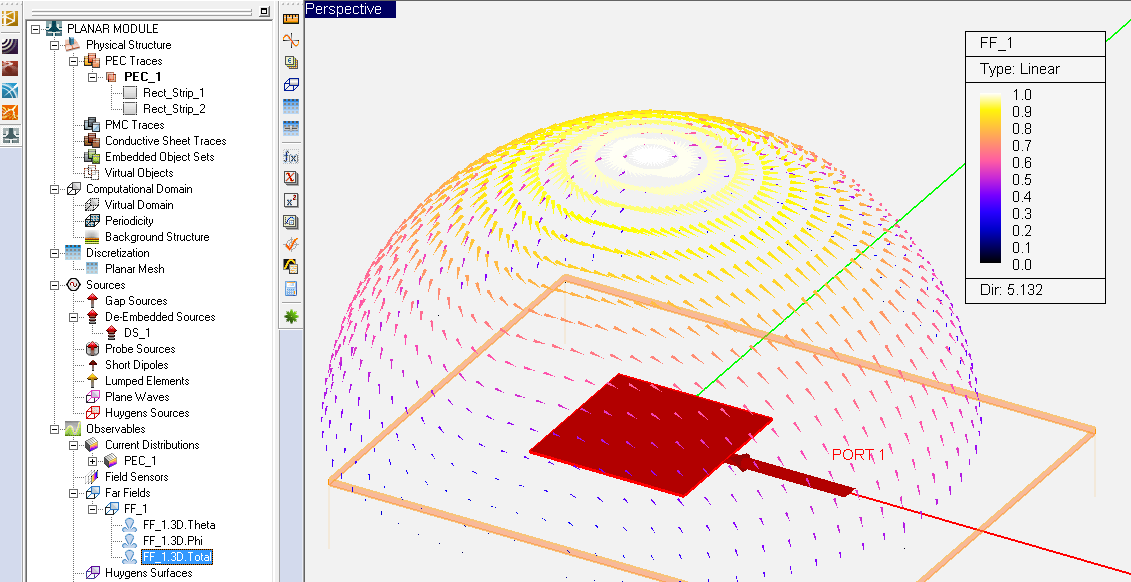

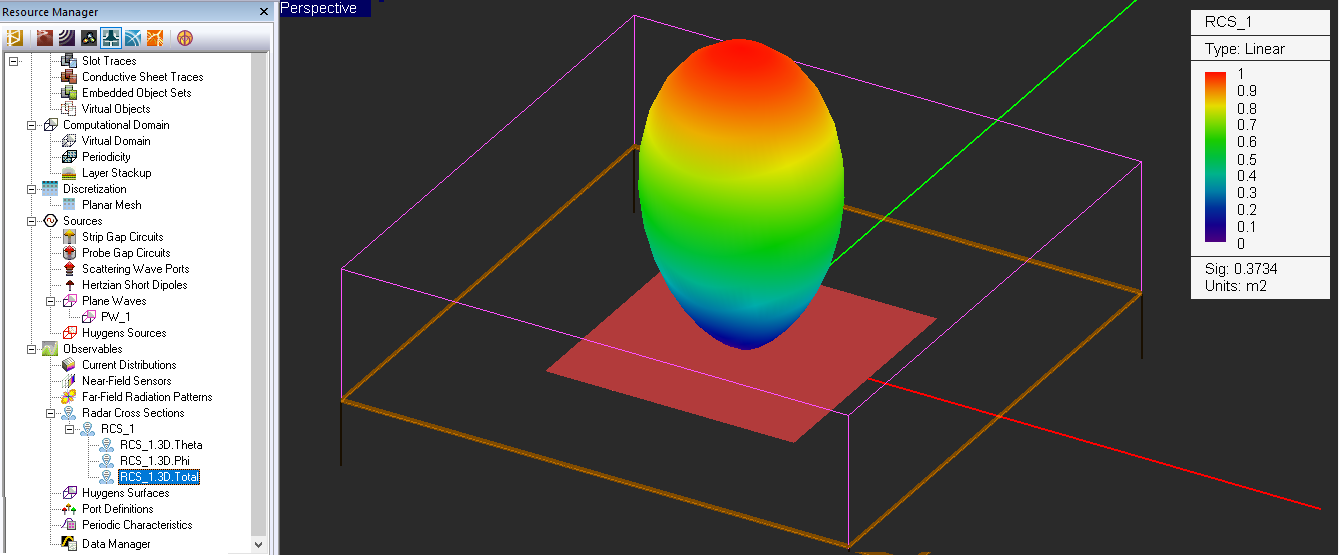

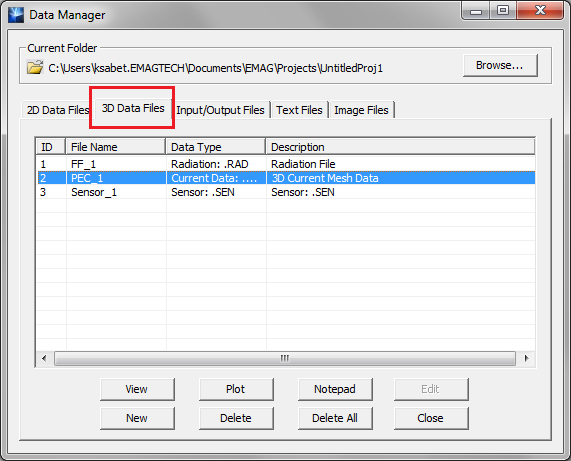

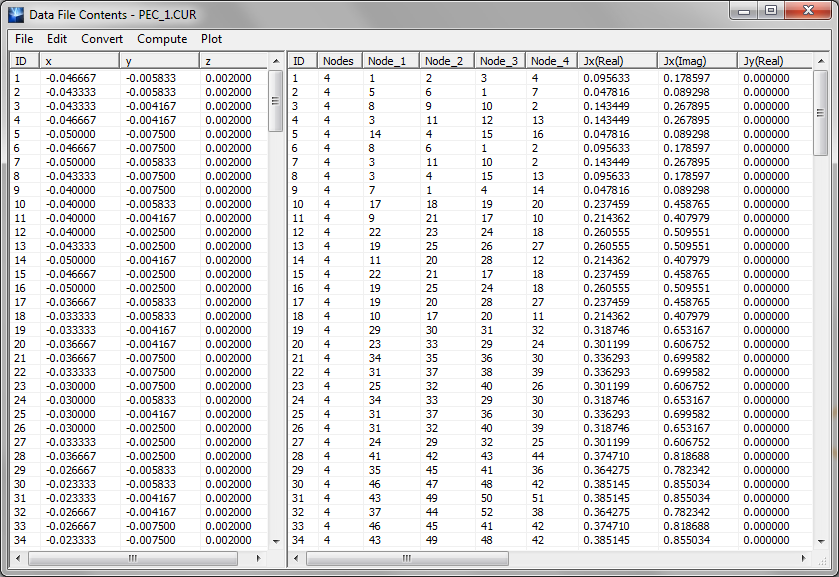

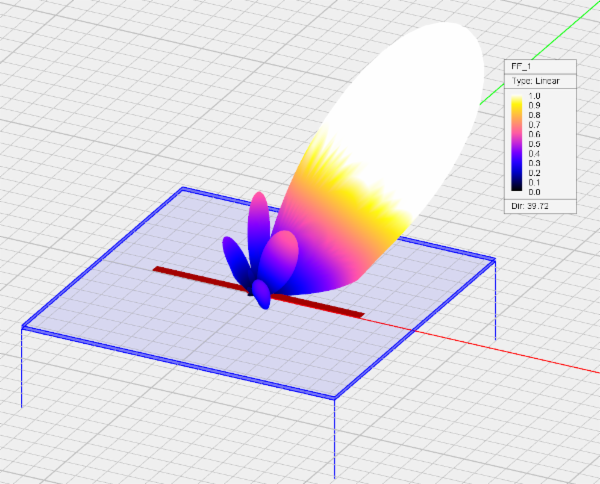

3D output data, on the other hand, are defined as functions of the space coordinates and are usually of vectorial nature. Cartesian-type and mesh-type data such as current distributions and near-field field distributions are expressed as functions of the Cartesian (X, Y, Z) coordinates. Spherical-type data like far-field radiation patterns and RCS are expressed as functions of the spherical angles (θ, φ). The 3D radiation patterns are written into a file with a "'''.RAD'''" extension. This file contains the complex values of the θ- and φ-components of the far-zone electric field (E<sub>θ</sub> and E<sub>φ</sub>) as well as the total far field magnitude as functions of the spherical observation angles θ and φ. The 3D RCS patterns are written into a file with a "'''.RCS'''" extension. This file contains the real values of the θ- and φ-polarized RCS values as well as the total RCS as functions of the spherical observation angles θ and φ. The current distributions are written into data files with a "'''.CUR'''" extension. They contain the real and imaginary parts of the X, Y and Z components of electric ('''J''') and magnetic ('''M''') current on each cells together with the definition of all the node coordinates and node indices of the cells. The near-field distributions are written into data files with a "'''.SEN'''" extension. They contain the amplitude and phase of the X, Y and Z components of electric ('''E''') and magnetic ('''H''') fields as functions of the coordinates of sampling points. All the 3D data files are listed in the '''3D Data Files''' tab of EM.Cube's '''Data Manager'''. You can view the contents of these data files by selecting their row in the data manager and clicking the '''View''' button of the dialog. | 3D output data, on the other hand, are defined as functions of the space coordinates and are usually of vectorial nature. Cartesian-type and mesh-type data such as current distributions and near-field field distributions are expressed as functions of the Cartesian (X, Y, Z) coordinates. Spherical-type data like far-field radiation patterns and RCS are expressed as functions of the spherical angles (θ, φ). The 3D radiation patterns are written into a file with a "'''.RAD'''" extension. This file contains the complex values of the θ- and φ-components of the far-zone electric field (E<sub>θ</sub> and E<sub>φ</sub>) as well as the total far field magnitude as functions of the spherical observation angles θ and φ. The 3D RCS patterns are written into a file with a "'''.RCS'''" extension. This file contains the real values of the θ- and φ-polarized RCS values as well as the total RCS as functions of the spherical observation angles θ and φ. The current distributions are written into data files with a "'''.CUR'''" extension. They contain the real and imaginary parts of the X, Y and Z components of electric ('''J''') and magnetic ('''M''') current on each cells together with the definition of all the node coordinates and node indices of the cells. The near-field distributions are written into data files with a "'''.SEN'''" extension. They contain the amplitude and phase of the X, Y and Z components of electric ('''E''') and magnetic ('''H''') fields as functions of the coordinates of sampling points. All the 3D data files are listed in the '''3D Data Files''' tab of EM.Cube's '''Data Manager'''. You can view the contents of these data files by selecting their row in the data manager and clicking the '''View''' button of the dialog. | ||

| Line 992: | Line 995: | ||

=== Standard vs. Custom Output === | === Standard vs. Custom Output === | ||

| − | At the end of a planar MoM simulation, a number of computed quantities are designated as "Standard Output" parameters and can be used for various post-processing data operations. For example, you can define design objectives based on them, which you need for optimization. The table below gives a list of all the currently available standard output parameters in EM.Cube's [[Planar Module]]: | + | At the end of a planar MoM simulation, a number of computed quantities are designated as "Standard Output" parameters and can be used for various post-processing data operations. For example, you can define design objectives based on them, which you need for [[optimization]]. The table below gives a list of all the currently available standard output parameters in EM.Cube's [[Planar Module]]: |

{| class="wikitable" | {| class="wikitable" | ||

| Line 1,144: | Line 1,147: | ||

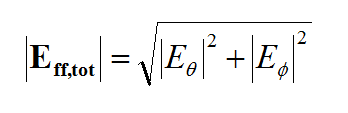

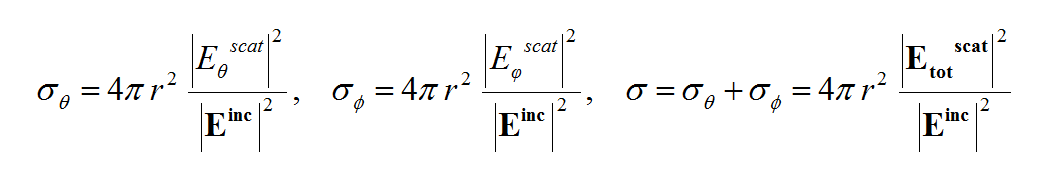

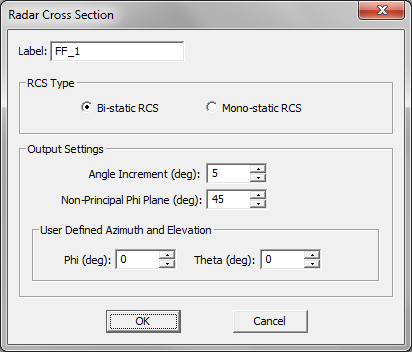

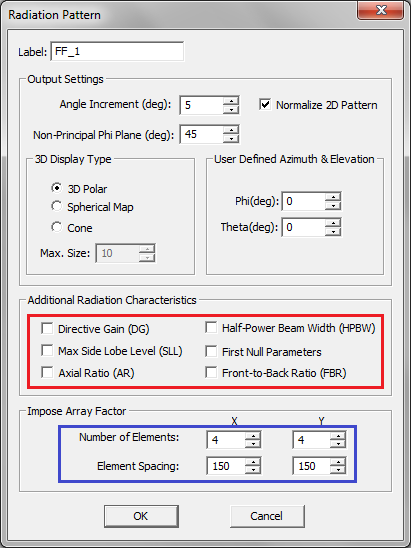

All the radiation- and scattering-related standard outputs are available only if you have defined a radiation pattern far field observable or an RCS far field observable, respectively. The standard output parameters DGU and ARU are the directive gain and axial ratio calculated at the certain user defined direction with spherical observation angles (θ, φ). These angles are specified in degrees as '''User Defined Azimuth & Elevation''' in the "Output Settings" section of the '''Radiation Pattern Dialog'''. The standard output parameters HPBWU, SLLU, FNBU and FNLU are determined at a user defined f-plane cut. This azimuth angle is specified in degrees as '''Non-Principal Phi Plane''' in the "Output Settings" section of the '''Radiation Pattern Dialog''', and its default value is 45°. The standard output parameters BRCS and MRCS are the total back-scatter RCS and the maximum total RCS of your planar structure when it is excited by an incident plane wave source at the specified θ<sub>s</sub> and φ<sub>s</sub> source angles. FRCS, on the other hand, is the total forward-scatter RCS measured at the predetermined θ<sub>o</sub> and φ<sub>o</sub> observation angles. These angles are specified in degrees as '''User Defined Azimuth & Elevation''' in the "Output Settings" section of the '''Radar Cross Section Dialog'''. The default values of the user defined azimuth and elevation are both zero corresponding to the zenith. | All the radiation- and scattering-related standard outputs are available only if you have defined a radiation pattern far field observable or an RCS far field observable, respectively. The standard output parameters DGU and ARU are the directive gain and axial ratio calculated at the certain user defined direction with spherical observation angles (θ, φ). These angles are specified in degrees as '''User Defined Azimuth & Elevation''' in the "Output Settings" section of the '''Radiation Pattern Dialog'''. The standard output parameters HPBWU, SLLU, FNBU and FNLU are determined at a user defined f-plane cut. This azimuth angle is specified in degrees as '''Non-Principal Phi Plane''' in the "Output Settings" section of the '''Radiation Pattern Dialog''', and its default value is 45°. The standard output parameters BRCS and MRCS are the total back-scatter RCS and the maximum total RCS of your planar structure when it is excited by an incident plane wave source at the specified θ<sub>s</sub> and φ<sub>s</sub> source angles. FRCS, on the other hand, is the total forward-scatter RCS measured at the predetermined θ<sub>o</sub> and φ<sub>o</sub> observation angles. These angles are specified in degrees as '''User Defined Azimuth & Elevation''' in the "Output Settings" section of the '''Radar Cross Section Dialog'''. The default values of the user defined azimuth and elevation are both zero corresponding to the zenith. | ||

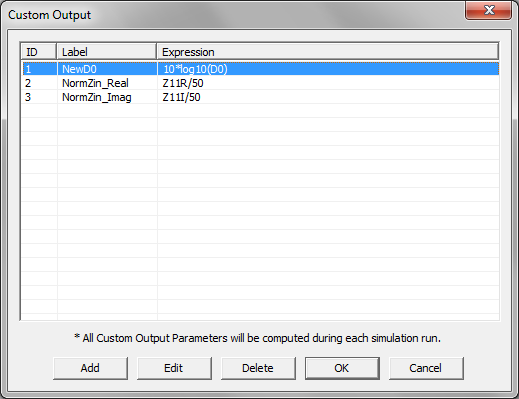

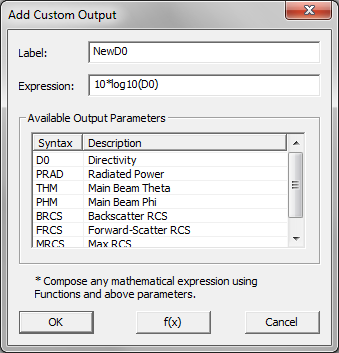

| − | If you are interested in calculating certain quantities at the end of a simulation, which you do not find among EM.Cube's standard output data, you can define your own custom output. EM.Cube allows you to define new custom output as any mathematical expression that involves the available standard output parameters, numbers, variables and all of EM.Cube's mathematical functions. For a list of legitimate mathematical functions, click the '''Functions [[File:functions_icon.png]]'''button of the '''Simulate Toolbar''' or select '''Simulate > Functions...'''from the menu bar, or use the keyboard shortcut '''Ctrl+I''' to open the Function Dialog. Here you can see a list of all the available EM.Cube functions with their syntax and a brief description. To define a custom output, click the '''Custom Output [[File:custom_icon.png]]'''button of the '''Simulate Toolbar''' or select '''Simulate > Custom Output...'''from the menu bar, or use the keyboard shortcut '''Ctrl+K''' to open the Custom Output Dialog. This dialog has a list of all of your custom output parameters. Initially, the list empty. You can define a new custom output by clicking the '''Add''' button of the dialog to open up the '''Add Custom Output Dialog'''. In this dialog, first you have to choose a new label for your new parameter and then define a mathematical expression for it. At the bottom of the dialog you can see a list of all the available standard output parameters, whose number and variety depends on your project's source type as well as the defined project observables. When you close the Add Custom Output dialog, it returns you to the Custom Output dialog, where the parameter list now reflects your newly defined custom output. You can edit an existing parameter by selecting its row in the table and clicking the '''Edit''' button, or you can delete any parameter from the list using the '''Delete''' button. | + | If you are interested in calculating certain quantities at the end of a simulation, which you do not find among EM.Cube's standard output data, you can define your own custom output. EM.Cube allows you to define new custom output as any mathematical expression that involves the available standard output parameters, numbers, [[variables]] and all of EM.Cube's mathematical functions. For a list of legitimate mathematical functions, click the '''Functions [[File:functions_icon.png]]'''button of the '''Simulate Toolbar''' or select '''Simulate > Functions...'''from the menu bar, or use the keyboard shortcut '''Ctrl+I''' to open the Function Dialog. Here you can see a list of all the available EM.Cube functions with their syntax and a brief description. To define a custom output, click the '''Custom Output [[File:custom_icon.png]]'''button of the '''Simulate Toolbar''' or select '''Simulate > Custom Output...'''from the menu bar, or use the keyboard shortcut '''Ctrl+K''' to open the Custom Output Dialog. This dialog has a list of all of your custom output parameters. Initially, the list empty. You can define a new custom output by clicking the '''Add''' button of the dialog to open up the '''Add Custom Output Dialog'''. In this dialog, first you have to choose a new label for your new parameter and then define a mathematical expression for it. At the bottom of the dialog you can see a list of all the available standard output parameters, whose number and variety depends on your project's source type as well as the defined project observables. When you close the Add Custom Output dialog, it returns you to the Custom Output dialog, where the parameter list now reflects your newly defined custom output. You can edit an existing parameter by selecting its row in the table and clicking the '''Edit''' button, or you can delete any parameter from the list using the '''Delete''' button. |

[[File:PMOM141.png]] | [[File:PMOM141.png]] | ||

| Line 1,184: | Line 1,187: | ||

=== Running a Parametric Sweep === | === Running a Parametric Sweep === | ||

| − | Parametric sweep is EM.Cube's most versatile sweep type. During a parametric sweep, the values of one or more sweep variables are varied over their specified ranges, and the planar MoM simulation is run for each combination of variable samples. If you define two or more sweep variables, the process will then involve nested sweep loops that follow the order of definition of the sweep variables. The topmost sweep variable in the list will form the outermost nested loop, and the sweep variable at the bottom of the list will form the innermost nested loop. Note that you can alternatively run either a frequency sweep or an angular sweep as parametric sweep, whereby the project frequency or the angles of incidence of a plane wave source are designated as sweep variables. Unlike optimization which will be discussed later, parametric sweeps are simple and straightforward and do not required careful advance planning. | + | Parametric sweep is EM.Cube's most versatile sweep type. During a parametric sweep, the values of one or more sweep [[variables]] are varied over their specified ranges, and the planar MoM simulation is run for each combination of variable samples. If you define two or more sweep [[variables]], the process will then involve nested sweep loops that follow the order of definition of the sweep [[variables]]. The topmost sweep variable in the list will form the outermost nested loop, and the sweep variable at the bottom of the list will form the innermost nested loop. Note that you can alternatively run either a frequency sweep or an angular sweep as parametric sweep, whereby the project frequency or the angles of incidence of a plane wave source are designated as sweep [[variables]]. Unlike [[optimization]] which will be discussed later, parametric sweeps are simple and straightforward and do not required careful advance planning. |

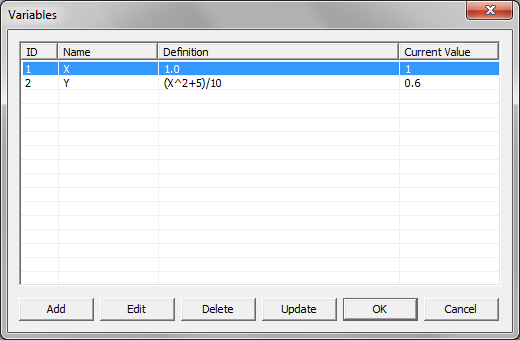

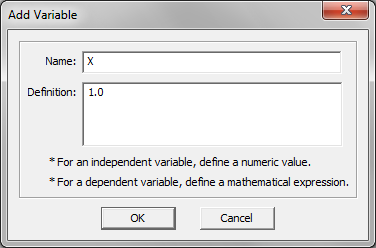

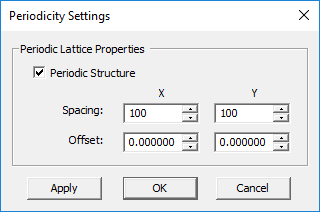

| − | Before you can run a parametric sweep, first you have to define one or more variables in your EM.Cube project. A variable is a mathematical entity that has a numeric value. This numeric value can be changed at your discretion at any time. You can define a variable either directly as a number or as a mathematical expression that may involve other previously defined variables. Even in the latter case, an "expression" variable has a numeric value at any time. You can designate almost any numeric quantity or parameter in EM.Cube as a variable. Or alternatively, you can associate a variable with almost anything in EM.Cube. This includes all the geometrical properties of CAD objects like coordinates, rotation angles, dimensions, etc. as well as material properties of object groups and background structure, source parameters, project frequency, mesh density, and unit cell periods in the case of a periodic structure. You can define a variable either in a formal manner using EM.Cube's Variable Dialog or directly from the project workspace or from the Navigation Tree. In the former "formal" option, first you open the Variables Dialog by clicking the '''Variables''' [[File:variable_icon_tn.png]] button of the '''Simulate Toolbar''' or selecting '''Menu > Simulate > Variables...'''or using the keyboard shortcut '''Ctrl+B'''. By default, the variable list is initially empty. To add a new variable, click the '''Add''' button to open the "Add Variable Dialog". Choose a '''Name''' for your new variable. In the box labeled '''Definition''', define your new variable either as an independent variable with a numeric value or as a dependent variable using a mathematical expression that involves previously defined variables. | + | Before you can run a parametric sweep, first you have to define one or more [[variables]] in your EM.Cube project. A variable is a mathematical entity that has a numeric value. This numeric value can be changed at your discretion at any time. You can define a variable either directly as a number or as a mathematical expression that may involve other previously defined [[variables]]. Even in the latter case, an "expression" variable has a numeric value at any time. You can designate almost any numeric quantity or parameter in EM.Cube as a variable. Or alternatively, you can associate a variable with almost anything in EM.Cube. This includes all the geometrical properties of CAD objects like coordinates, rotation angles, dimensions, etc. as well as material properties of object groups and background structure, source parameters, project frequency, mesh density, and unit cell periods in the case of a periodic structure. You can define a variable either in a formal manner using EM.Cube's Variable Dialog or directly from the project workspace or from the Navigation Tree. In the former "formal" option, first you open the [[Variables]] Dialog by clicking the '''[[Variables]]''' [[File:variable_icon_tn.png]] button of the '''Simulate Toolbar''' or selecting '''Menu > Simulate > [[Variables]]...'''or using the keyboard shortcut '''Ctrl+B'''. By default, the variable list is initially empty. To add a new variable, click the '''Add''' button to open the "Add Variable Dialog". Choose a '''Name''' for your new variable. In the box labeled '''Definition''', define your new variable either as an independent variable with a numeric value or as a dependent variable using a mathematical expression that involves previously defined [[variables]]. |

[[File:PMOM146(1).png]] | [[File:PMOM146(1).png]] | ||

| − | Figure 1: EM.Cube's Variables dialog. | + | Figure 1: EM.Cube's [[Variables]] dialog. |

[[File:PMOM145(2).png]] | [[File:PMOM145(2).png]] | ||

| Line 1,196: | Line 1,199: | ||

Figure 2: Defining a new independent variable. | Figure 2: Defining a new independent variable. | ||

| − | Once you finish the definition of a new variable, its name and syntax (Definition) are added to the "Variable List". You can also see the '''Current Value''' of every variable at any time in the Variable as dialog. Note that at this stage, you have simply defined one or more variables, but you have not yet associated them with actual objects or project properties. Wherever you see a numeric value for a parameter in a dialog, e.g. the length of a rect strip object in its property dialog, you can replace the numeric value with a variable name or a mathematical expression using the names of the currently available variables. From this moment on, that parameter or quantity becomes tied up with the associated variable. This means that every time you change the value of that variable, the value of the associated object parameter or project property will change accordingly. You can change the value of a variable directly from the Variables Dialog using the '''Edit''' button or indirectly during a parametric sweep. In the former case, you have to click the '''Update''' button of the Variables dialog to make the changes effective. Alternatively, you can define new variables directly from the property dialogs of CAD objects, trace and object set dialogs, stack-up dialog or many other EM.Cube dialogs. If you replace the numeric value of a parameter with a text-string name that has not already been defined as a variable, then a new variable by that name is created and added to the "Variable List". The numeric value of the associated parameter at the time of replacement is taken as the "current Value" of the newly created variable. In this way, you can easily and quickly define variables associated with the design parameters that you intend to sweep in your project. | + | Once you finish the definition of a new variable, its name and syntax (Definition) are added to the "Variable List". You can also see the '''Current Value''' of every variable at any time in the Variable as dialog. Note that at this stage, you have simply defined one or more [[variables]], but you have not yet associated them with actual objects or project properties. Wherever you see a numeric value for a parameter in a dialog, e.g. the length of a rect strip object in its property dialog, you can replace the numeric value with a variable name or a mathematical expression using the names of the currently available [[variables]]. From this moment on, that parameter or quantity becomes tied up with the associated variable. This means that every time you change the value of that variable, the value of the associated object parameter or project property will change accordingly. You can change the value of a variable directly from the [[Variables]] Dialog using the '''Edit''' button or indirectly during a parametric sweep. In the former case, you have to click the '''Update''' button of the [[Variables]] dialog to make the changes effective. Alternatively, you can define new [[variables]] directly from the property dialogs of CAD objects, trace and object set dialogs, stack-up dialog or many other EM.Cube dialogs. If you replace the numeric value of a parameter with a text-string name that has not already been defined as a variable, then a new variable by that name is created and added to the "Variable List". The numeric value of the associated parameter at the time of replacement is taken as the "current Value" of the newly created variable. In this way, you can easily and quickly define [[variables]] associated with the design parameters that you intend to sweep in your project. |

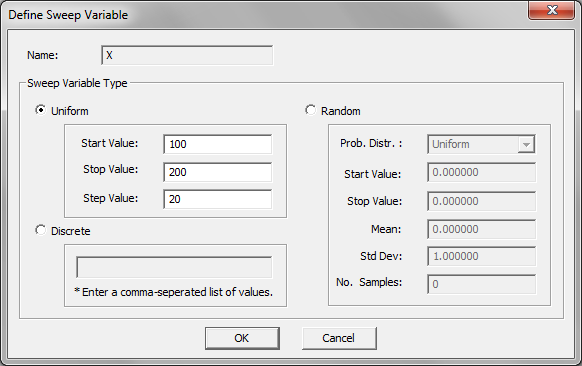

| − | In a parametric sweep, you can vary the values of one or more "Independent" project variables. In other words, you designate one or more independent variables as sweep variables and specify how they should vary (be sampled) during the sweep simulation process. In EM.Cube you can define three types of sweep variables: '''Uniform''', '''Discrete''' and '''Random'''. Each sweep variables can be defined as one of these three types, and you can mix sweep variables of different types in a multivariable parametric sweep. A uniform sweep variable is defined by a "Start" and "End" value and is incremented by a predetermined "Step" value during a sweep. A discrete sweep variable is defined by a discrete set of values and takes on these values by the order of their list during a sweep. A random sweep variable, on the other hand, takes on random values during a sweep according to a specified probability distribution. EM.Cube currently offers two random distribution types. '''Uniform Distribution''' is defined by "Minimum" and "Maximum" values, while '''Normal (Gaussian) Distribution''' is defined by a "Mean" and "Standard Deviation". You need to specify the "Number of Samples" for both random variable types. | + | In a parametric sweep, you can vary the values of one or more "Independent" project [[variables]]. In other words, you designate one or more independent [[variables]] as sweep [[variables]] and specify how they should vary (be sampled) during the sweep simulation process. In EM.Cube you can define three types of sweep [[variables]]: '''Uniform''', '''Discrete''' and '''Random'''. Each sweep [[variables]] can be defined as one of these three types, and you can mix sweep [[variables]] of different types in a multivariable parametric sweep. A uniform sweep variable is defined by a "Start" and "End" value and is incremented by a predetermined "Step" value during a sweep. A discrete sweep variable is defined by a discrete set of values and takes on these values by the order of their list during a sweep. A random sweep variable, on the other hand, takes on random values during a sweep according to a specified probability distribution. EM.Cube currently offers two random distribution types. '''Uniform Distribution''' is defined by "Minimum" and "Maximum" values, while '''Normal (Gaussian) Distribution''' is defined by a "Mean" and "Standard Deviation". You need to specify the "Number of Samples" for both random variable types. |

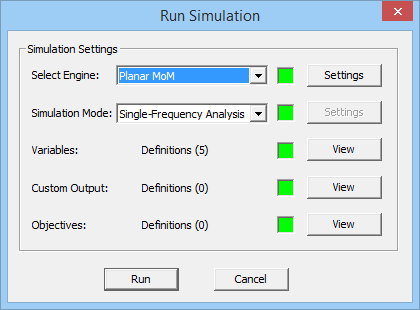

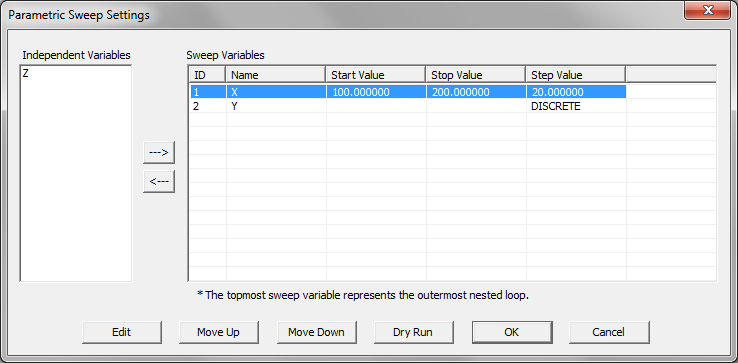

| − | To define sweep variables and run a parametric sweep, open the '''Simulation Run Dialog''', and select the '''Parametric Sweep''' option from the dropdown list labeled '''Simulation Mode'''. When you choose the parametric sweep option, the '''Settings''' button next to the simulation mode dropdown list becomes enabled. Clicking this button opens the '''Parametric Sweep Settings''' dialog. The '''Sweep Variables List''' is initially empty. On the left side of the dialog you see the "'''Independent Variables Table'''", which lists all the available independent variables of your project. Select an independent variable from the table and use the right arrow ('''-->''') button of the dialog to move it to the Sweep Variables List. Before moving the variable to the new location, the "Define Sweep Variable Dialog" opens up, where you have to define the attributes of your new sweep variable. In this dialog, you need to choose the type of the sweep variable using the three radio buttons labeled '''Uniform''', '''Discrete''' and '''Random'''. Depending on your choice, the proper section of the dialog becomes enabled, where you can define the range of your sweep variable and other relevant parameters. | + | To define sweep [[variables]] and run a parametric sweep, open the '''Simulation Run Dialog''', and select the '''Parametric Sweep''' option from the dropdown list labeled '''Simulation Mode'''. When you choose the parametric sweep option, the '''Settings''' button next to the simulation mode dropdown list becomes enabled. Clicking this button opens the '''Parametric Sweep Settings''' dialog. The '''Sweep [[Variables]] List''' is initially empty. On the left side of the dialog you see the "'''Independent [[Variables]] Table'''", which lists all the available independent [[variables]] of your project. Select an independent variable from the table and use the right arrow ('''-->''') button of the dialog to move it to the Sweep [[Variables]] List. Before moving the variable to the new location, the "Define Sweep Variable Dialog" opens up, where you have to define the attributes of your new sweep variable. In this dialog, you need to choose the type of the sweep variable using the three radio buttons labeled '''Uniform''', '''Discrete''' and '''Random'''. Depending on your choice, the proper section of the dialog becomes enabled, where you can define the range of your sweep variable and other relevant parameters. |

| − | Once you finish the definition of a sweep variable, its name and attributes are added to the Sweep Variables List. Note that you can change your mind and remove a sweep variable from the list. To do so, select its name or row from the list and use the left arrow (<--) button to move it back to the Independent Variables Table. You can also change the type or relevant values of a sweep variable after it has been defined. Select the variable and click the '''Edit''' button of the dialog. As mentioned earlier, the order of the sweep variables in the list determined the structure of the nested sweep loops in a multivariable sweep process. When you have two or more sweep variables in the list, you can change their order using the '''Move Up''' and '''Move Down''' buttons. | + | Once you finish the definition of a sweep variable, its name and attributes are added to the Sweep [[Variables]] List. Note that you can change your mind and remove a sweep variable from the list. To do so, select its name or row from the list and use the left arrow (<--) button to move it back to the Independent [[Variables]] Table. You can also change the type or relevant values of a sweep variable after it has been defined. Select the variable and click the '''Edit''' button of the dialog. As mentioned earlier, the order of the sweep [[variables]] in the list determined the structure of the nested sweep loops in a multivariable sweep process. When you have two or more sweep [[variables]] in the list, you can change their order using the '''Move Up''' and '''Move Down''' buttons. |

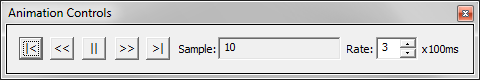

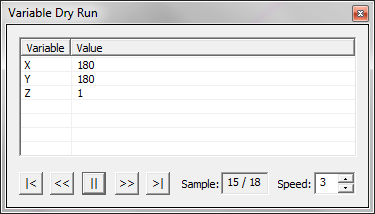

| − | The Parametric Sweep Settings dialog also features another useful button labeled '''Dry Run''', which runs a "fake" sweep animation. During a dry run, the sweep variables are varied sample by sample and all of their associated parameters in the project workspace are updated at each run. However, the simulation engine is not called during a dry run, and no numerical computations take place at all. Also, the Variable Dry Run dialog appears on the screen which shows the changing values of all the variables at all times. This dialog works in a similar way as the Animation Controls Dialog described earlier. You can change the speed of the updates or control them manually using the motion buttons. The dry run process continues forever until to stop it by clicking the close (X) button of the Dry Run dialog of simply hitting the keyboard's '''Esc Key'''. At ach update of a dry run, you can see how the CAD objects in your planar structure change. This is very useful to inspect the integrity of your structure and your defined variables before an actual simulation run. If you run a dry run while EM.Cube is in the mesh view mode, then the planar mesh of your structure is updated for each combination of the sweep variable samples during the dry run process. Once you are satisfied with the choice and definition of your sweep variables, close the Parametric Sweep Settings dialog to return to the Simulation Run dialog, where you can start the planar MoM parametric sweep simulation by clicking the '''Run''' button. | + | The Parametric Sweep Settings dialog also features another useful button labeled '''Dry Run''', which runs a "fake" sweep animation. During a dry run, the sweep [[variables]] are varied sample by sample and all of their associated parameters in the project workspace are updated at each run. However, the simulation engine is not called during a dry run, and no numerical computations take place at all. Also, the Variable Dry Run dialog appears on the screen which shows the changing values of all the [[variables]] at all times. This dialog works in a similar way as the Animation Controls Dialog described earlier. You can change the speed of the updates or control them manually using the motion buttons. The dry run process continues forever until to stop it by clicking the close (X) button of the Dry Run dialog of simply hitting the keyboard's '''Esc Key'''. At ach update of a dry run, you can see how the CAD objects in your planar structure change. This is very useful to inspect the integrity of your structure and your defined [[variables]] before an actual simulation run. If you run a dry run while EM.Cube is in the mesh view mode, then the planar mesh of your structure is updated for each combination of the sweep variable samples during the dry run process. Once you are satisfied with the choice and definition of your sweep [[variables]], close the Parametric Sweep Settings dialog to return to the Simulation Run dialog, where you can start the planar MoM parametric sweep simulation by clicking the '''Run''' button. |

[[File:PMOM148.png]] | [[File:PMOM148.png]] | ||

| Line 1,220: | Line 1,223: | ||

=== Optimizing Planar Structures === | === Optimizing Planar Structures === | ||

| − | Optimization is a process in which the values of one or more variables are varied in a systematic way until one or more design objectives are met. The design objectives are typically defined based on the output simulation data and are mathematically translated into an error (objective) function that is to be minimized. Running a successful optimization requires careful advance planning. First you have to make sure that your optimization problem does have a valid solution within the range of your optimization variables. In other words, the design objectives must be achievable for at least one combination of the optimization variable values within the specified ranges. Otherwise, the optimization process will not converge or will exhaust the maximum allowed number of iteration cycles and exit unsuccessfully. | + | [[Optimization]] is a process in which the values of one or more [[variables]] are varied in a systematic way until one or more design objectives are met. The design objectives are typically defined based on the output simulation data and are mathematically translated into an error (objective) function that is to be minimized. Running a successful [[optimization]] requires careful advance planning. First you have to make sure that your [[optimization]] problem does have a valid solution within the range of your [[optimization]] [[variables]]. In other words, the design objectives must be achievable for at least one combination of the [[optimization]] variable values within the specified ranges. Otherwise, the [[optimization]] process will not converge or will exhaust the maximum allowed number of iteration cycles and exit unsuccessfully. |

| − | An optimization process in EM.Cube involves several steps as follows: | + | An [[optimization]] process in EM.Cube involves several steps as follows: |

| − | # Define project (design) variables and designate one or more optimization variables with respective ranges. | + | # Define project (design) [[variables]] and designate one or more [[optimization]] [[variables]] with respective ranges. |

# Define project (design) objectives using a combination of standard and custom output parameters. | # Define project (design) objectives using a combination of standard and custom output parameters. | ||

| − | # (Optional but Highly Recommended) Run a parametric sweep of your optimization variables within their specified ranges and see if your design objectives have any chance of ever being met. | + | # (Optional but Highly Recommended) Run a parametric sweep of your [[optimization]] [[variables]] within their specified ranges and see if your design objectives have any chance of ever being met. |

| − | # Choose the optimization algorithm type and set its relevant parameters. | + | # Choose the [[optimization]] algorithm type and set its relevant parameters. |

# If you have more than one design objective, define weights for the goals. | # If you have more than one design objective, define weights for the goals. | ||

| − | # Run the optimization process and wait until it is completed. | + | # Run the [[optimization]] process and wait until it is completed. |

| − | # Examine the optimal values of the participating variables and the updated values of their associated parameters. | + | # Examine the optimal values of the participating [[variables]] and the updated values of their associated parameters. |

| − | # Run an analysis using the optimal variable values and validate the optimization results. | + | # Run an analysis using the optimal variable values and validate the [[optimization]] results. |

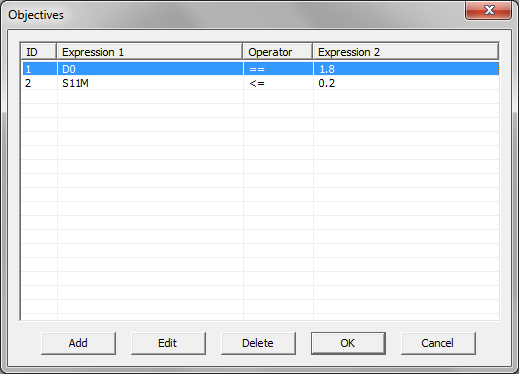

| − | A design objective is a logical expression that consists of two mathematical expressions separated by one of the logical operators: ==, <, <=, > or >=. These are called the left-hand-side (LHS) and right-hand-side (RHS) mathematical expressions and both must have computable numerical values. They may contain any combination of numbers, constants, variables, standard or custom output parameters as well as EM.Cube's legitimate functions. Objectives that involve the logical operator "'''=='''" are regarded a "'''Goals'''". The RHS expression of a goal is usually chosen to be a number, which is often known as the "'''Target Value'''". In the logical expression of a goal, one can bring the two RHS and LHS expressions to one side establish an equality of the form "(LHS - RHS) == 0". Numerically speaking, this is equivalent to minimizing the quantity | LHS - RHS |. During an optimization process, all the project goals are evaluated numerically and they are used collectively to build an error (objective) function whose value is tried to be minimized. Objectives that involve "non-Equal" logical operators are regarded a "'''Constraints'''". Unlike goals which lead to minimizable numerical values, constraints are rather conditions that should be met while the error function is being minimized. | + | A design objective is a logical expression that consists of two mathematical expressions separated by one of the logical operators: ==, <, <=, > or >=. These are called the left-hand-side (LHS) and right-hand-side (RHS) mathematical expressions and both must have computable numerical values. They may contain any combination of numbers, constants, variables, standard or custom output parameters as well as EM.Cube's legitimate functions. Objectives that involve the logical operator "'''=='''" are regarded a "'''Goals'''". The RHS expression of a goal is usually chosen to be a number, which is often known as the "'''Target Value'''". In the logical expression of a goal, one can bring the two RHS and LHS expressions to one side establish an equality of the form "(LHS - RHS) == 0". Numerically speaking, this is equivalent to minimizing the quantity | LHS - RHS |. During an [[optimization]] process, all the project goals are evaluated numerically and they are used collectively to build an error (objective) function whose value is tried to be minimized. Objectives that involve "non-Equal" logical operators are regarded a "'''Constraints'''". Unlike goals which lead to minimizable numerical values, constraints are rather conditions that should be met while the error function is being minimized. |

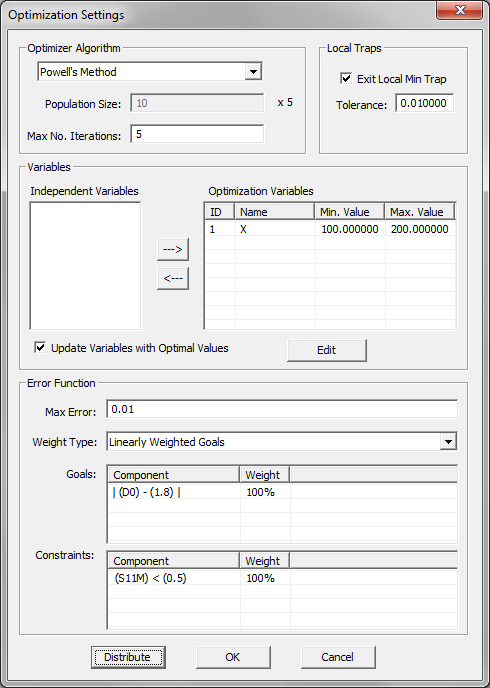

To define an objective, open the '''Objectives Dialog''' either by clicking the '''Objectives''' [[File:objective_icon.png]] button of the '''Simulate Toolbar''', or by selecting '''Menu > Simulate > Objectives...''' from the Menu Bar, or using the keyboard shortcut '''Ctrl+J'''. The objectives list is initially empty. To add a new objective, click the '''Add''' button to open up the '''Add Objective Dialog'''. At the bottom of this dialog, you can see a list of all the available EM.Cube output parameters including both standard and custom output parameters. This list may vary depending on the types of sources and observables that you have already defined in your project. You can enter any mathematical expressions in the two boxes labeled '''Expression 1''' and '''Expression 2'''. The Available Output Parameter List simply helps you remember the syntax of these parameters. You should also select one of the available options in the dropdown list labeled '''Logical Operator'''. The default operator is '''"=== (Equal To)"'''. As soon as you finish the definition of an objective, its full logical expression is added to the Objective List. You can always modify the project objectives after they have been created. Select a row in the Objective List and click the '''Edit''' button of the dialog and change the expressions or the logical operator. You can also remove an objective from the list using the '''Delete''' button. | To define an objective, open the '''Objectives Dialog''' either by clicking the '''Objectives''' [[File:objective_icon.png]] button of the '''Simulate Toolbar''', or by selecting '''Menu > Simulate > Objectives...''' from the Menu Bar, or using the keyboard shortcut '''Ctrl+J'''. The objectives list is initially empty. To add a new objective, click the '''Add''' button to open up the '''Add Objective Dialog'''. At the bottom of this dialog, you can see a list of all the available EM.Cube output parameters including both standard and custom output parameters. This list may vary depending on the types of sources and observables that you have already defined in your project. You can enter any mathematical expressions in the two boxes labeled '''Expression 1''' and '''Expression 2'''. The Available Output Parameter List simply helps you remember the syntax of these parameters. You should also select one of the available options in the dropdown list labeled '''Logical Operator'''. The default operator is '''"=== (Equal To)"'''. As soon as you finish the definition of an objective, its full logical expression is added to the Objective List. You can always modify the project objectives after they have been created. Select a row in the Objective List and click the '''Edit''' button of the dialog and change the expressions or the logical operator. You can also remove an objective from the list using the '''Delete''' button. | ||

| Line 1,245: | Line 1,248: | ||

Figure 2: Defining a new objective using a list of available output parameters. | Figure 2: Defining a new objective using a list of available output parameters. | ||

| − | Just like sweep variables, optimization variables are chosen from the list of available independent variables already defined in your project. Dependent variables do not participate directly in an optimization process, although their values continuously change in accordance with their associated independent variables. In fact, dependent variables let you envision and formulate very complicated constrained optimization scenarios. | + | Just like sweep [[variables]], [[optimization]] [[variables]] are chosen from the list of available independent [[variables]] already defined in your project. Dependent [[variables]] do not participate directly in an [[optimization]] process, although their values continuously change in accordance with their associated independent [[variables]]. In fact, dependent [[variables]] let you envision and formulate very complicated constrained [[optimization]] scenarios. |

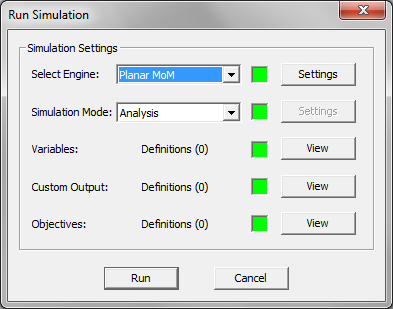

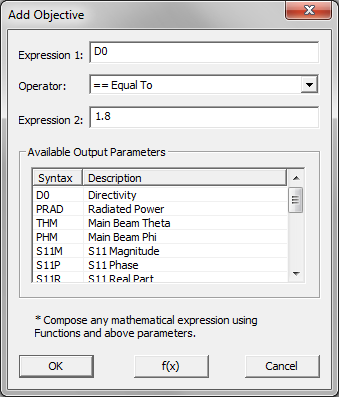

| − | To define optimization variables and perform an optimization, open the '''Simulation Run Dialog''', and select the '''Optimization''' option from the dropdown list labeled '''Simulation Mode'''. When you choose the optimization option, the '''Settings''' button next to the simulation mode dropdown list becomes enabled. Clicking this button opens the '''Optimization Settings''' dialog. This is a large dialog with several distinct sections. In the section titled "'''Optimization Algorithm'''", you can choose one of EM.Cube's three currently available optimizers: '''Powell's Method''', '''Basic Genetic Algorithm''' and '''Fast Pareto Genetic Algorithm'''. For all three optimizers you have to set the '''Maximum Number of Iterations''', which has a default value of 5. For the two genetic algorithms, basic GA and Pareto, you also need to set the '''Population Size''' as a multiple of 5. The default population size is 50. | + | To define [[optimization]] [[variables]] and perform an [[optimization]], open the '''Simulation Run Dialog''', and select the '''[[Optimization]]''' option from the dropdown list labeled '''Simulation Mode'''. When you choose the [[optimization]] option, the '''Settings''' button next to the simulation mode dropdown list becomes enabled. Clicking this button opens the '''[[Optimization]] Settings''' dialog. This is a large dialog with several distinct sections. In the section titled "'''[[Optimization]] Algorithm'''", you can choose one of EM.Cube's three currently available optimizers: '''Powell's Method''', '''Basic Genetic Algorithm''' and '''Fast Pareto Genetic Algorithm'''. For all three optimizers you have to set the '''Maximum Number of Iterations''', which has a default value of 5. For the two genetic algorithms, basic GA and Pareto, you also need to set the '''Population Size''' as a multiple of 5. The default population size is 50. |

| − | In the Variables section of the dialog, you designate the optimization variables. This is very similar to how you assign sweep variables in a parametric sweep as discussed earlier. The '''Optimization Variables List''' is initially empty. On the left side of the dialog you see the "'''Independent Variables Table'''", which lists all the available independent variables of your project. Select an independent variable from the table and use the right arrow ('''-->''') button of the dialog to move it to the Optimization Variable List. Before moving the variable to the new location, the "Define Optimization Variable Dialog" opens up, where you have to set the '''Minimum'''and '''Maximum'''values of your new optimization variable. Once you finish the definition of an optimization variable, its name and Min/Max values are added to the Optimization Variables List. Note that you can change your mind and remove an optimization variable from the list. To do so, select its name or row from the list and use the left arrow (<--) button to move it back to the Independent Variables Table. You can also change the Min/Max values of an optimization variable after it has been defined. Select the variable and click the '''Edit''' button of the dialog to change those value. If you check the box labeled "''' Update Variables with Optimal Values'''" (as it is always checked by default), EM.Cube will automatically replace the definitions (and current values) of all the participating optimization variables in the '''Variables Dialog''' with their computed optimal values and will update all the associated parameters in the project workspace. This, of course, will happen only if the optimization process successfully converges. Sometimes, the optimization process may get trapped in a local minimum. You may encounter this problem primarily when using the Powell method. You will notice that the values of the optimization variables soon get "saturated" and remain constant afterwards. EM.Cube lets you exit such local traps if you check the box labeled "'''Exit Local Min Trap'''". There is a box underneath, labeled '''Tolerance''', that becomes enabled and has a default value of 0.01. This means that exit a local minimum trap when the value of the optimization variable stays within 1% error after successive optimization runs. In that case, the optimization process ends forcibly before having achieved convergence. | + | In the [[Variables]] section of the dialog, you designate the [[optimization]] [[variables]]. This is very similar to how you assign sweep [[variables]] in a parametric sweep as discussed earlier. The '''[[Optimization]] [[Variables]] List''' is initially empty. On the left side of the dialog you see the "'''Independent [[Variables]] Table'''", which lists all the available independent [[variables]] of your project. Select an independent variable from the table and use the right arrow ('''-->''') button of the dialog to move it to the [[Optimization]] Variable List. Before moving the variable to the new location, the "Define [[Optimization]] Variable Dialog" opens up, where you have to set the '''Minimum'''and '''Maximum'''values of your new [[optimization]] variable. Once you finish the definition of an [[optimization]] variable, its name and Min/Max values are added to the [[Optimization]] [[Variables]] List. Note that you can change your mind and remove an [[optimization]] variable from the list. To do so, select its name or row from the list and use the left arrow (<--) button to move it back to the Independent [[Variables]] Table. You can also change the Min/Max values of an [[optimization]] variable after it has been defined. Select the variable and click the '''Edit''' button of the dialog to change those value. If you check the box labeled "''' Update [[Variables]] with Optimal Values'''" (as it is always checked by default), EM.Cube will automatically replace the definitions (and current values) of all the participating [[optimization]] [[variables]] in the '''[[Variables]] Dialog''' with their computed optimal values and will update all the associated parameters in the project workspace. This, of course, will happen only if the [[optimization]] process successfully converges. Sometimes, the [[optimization]] process may get trapped in a local minimum. You may encounter this problem primarily when using the Powell method. You will notice that the values of the [[optimization]] [[variables]] soon get "saturated" and remain constant afterwards. EM.Cube lets you exit such local traps if you check the box labeled "'''Exit Local Min Trap'''". There is a box underneath, labeled '''Tolerance''', that becomes enabled and has a default value of 0.01. This means that exit a local minimum trap when the value of the [[optimization]] variable stays within 1% error after successive [[optimization]] runs. In that case, the [[optimization]] process ends forcibly before having achieved convergence. |

| − | Finally, in the section titled "'''Error Function'''" of the Optimization Dialog you build the mathematical form of your objective function. Keep in mind that EM.Cube's optimization is a numerical process. Therefore, you can rarely minimize your error function to zero literally. You need to set a "'''Maximum Error'''" value for the objective function, which terminates the process as "converged" when it is reached. The default value of Maximum Error is 0.01. In two tables labeled '''Goals''' and '''Constraints''', you see a list of all the project objectives that have been split between the two tables according to their types. Many optimization problems involve a single, straightforward goal. Others may involve multiple goals subject to multiple constraints. In those cases, you have assign weights to your goals and constraints. If all of your goals and constraints have the same level of importance, then you assign equal weights to them. You can do this easily by clicking the '''Distribute''' button of the dialog. Or you may assign individual weights manually. However, you have to make sure that all the weight adds up to unity. The objective function of the optimization problem is constructed from the goals and constraints using the specified weights. This can be done in two different ways: as '''Linearly Weighted Goals''' or as '''Mean Square Weighted Goals.''' You set these options from the dropdown list labeled '''Weight Type'''. Once you are satisfied with the choice and definition of your optimization variables, optimization algorithms and goals weights, close the Optimization dialog to return to the Simulation Run dialog, where you can start the planar MoM optimization process by clicking the '''Run''' button. | + | Finally, in the section titled "'''Error Function'''" of the [[Optimization]] Dialog you build the mathematical form of your objective function. Keep in mind that EM.Cube's [[optimization]] is a numerical process. Therefore, you can rarely minimize your error function to zero literally. You need to set a "'''Maximum Error'''" value for the objective function, which terminates the process as "converged" when it is reached. The default value of Maximum Error is 0.01. In two tables labeled '''Goals''' and '''Constraints''', you see a list of all the project objectives that have been split between the two tables according to their types. Many [[optimization]] problems involve a single, straightforward goal. Others may involve multiple goals subject to multiple constraints. In those cases, you have assign weights to your goals and constraints. If all of your goals and constraints have the same level of importance, then you assign equal weights to them. You can do this easily by clicking the '''Distribute''' button of the dialog. Or you may assign individual weights manually. However, you have to make sure that all the weight adds up to unity. The objective function of the [[optimization]] problem is constructed from the goals and constraints using the specified weights. This can be done in two different ways: as '''Linearly Weighted Goals''' or as '''Mean Square Weighted Goals.''' You set these options from the dropdown list labeled '''Weight Type'''. Once you are satisfied with the choice and definition of your [[optimization]] [[variables]], [[optimization]] algorithms and goals weights, close the [[Optimization]] dialog to return to the Simulation Run dialog, where you can start the planar MoM [[optimization]] process by clicking the '''Run''' button. |

[[File:PMOM152.png]] | [[File:PMOM152.png]] | ||

| − | Figure 3: EM.Cube's Optimization dialog. | + | Figure 3: EM.Cube's [[Optimization]] dialog. |

== Periodic Planar Structures & Antenna Arrays == | == Periodic Planar Structures & Antenna Arrays == | ||

Revision as of 18:17, 10 June 2013

The Method of Moments (MoM) is a rigorous, full-wave numerical technique for solving open boundary electromagnetic problems. Using this technique, you can analyze electromagnetic radiation, scattering and wave propagation problems with relatively short computation times and modest computing resources. The method of moments is an integral equation technique; it solves the integral form of Maxwell’s equations as opposed to their differential forms that are used in the finite element or finite difference time domain methods.

In a planar MoM simulation, the background structure is usually a layered planar structure that consists of one or more laterally infinite material layers. In EM.Cube’s Planar Module, the layered structure is stacked along the Z axis. In other words, the dimensions of the layers are infinite along the X and Y axes. Metallic traces are placed at the boundaries between the substrate or superstrate layers. These are modeled by perfect electric conductor (PEC) traces or conductive sheet traces of finite thickness and finite conductivity. Some layers might be separated by infinite perfectly conducting ground planes. The two sides of a ground plane can be electromagnetically coupled through one or several slots or apertures. Such slots or apertures are modeled by magnetic currents and are realized and represented by perfectly magnetic conductor (PMC) traces. Furthermore, the metallic traces can be interconnected or connected to ground planes using embedded objects. Such objects can be used to model circuit vias, plated-through holes or dielectric inserts. These are modeled as volume polarization currents.

The currents in a planar MoM simulation are discretized as a collection of elementary currents with small finite spatial extents. These elementary currents are called basis functions and obviously have a vectorial nature. The total currents (solution of the problem) are summations of these elementary currents. The basis functions are well defined and easy to calculate; however, their amplitudes are initially unknown in a MoM problem. Through the planar MoM solution, you find these unknown amplitudes. Once the total currents are known, you can calculate the fields everywhere in the structure.

Contents

- 1 A Planar Method Of Moments Primer

- 2 Anatomy Of A Planar Structure

- 2.1 Defining Layer Stack-Up

- 2.2 Editing Substrate Layers

- 2.3 Planar Object Types

- 2.4 Defining Traces & Object Sets

- 2.5 Drawing Planar Objects

- 2.6 Modeling Metallic Traces

- 2.7 Modeling Slot Traces

- 2.8 Defining Embedded Object Sets

- 2.9 Planar Module's Rules & Limitations

- 2.10 Managing Objects, Traces & Sets

- 3 Discretizing Planar Structures

- 3.1 The Planar MoM Mesh

- 3.2 The Rectangular Mesh Advantage

- 3.3 Generating A Planar Mesh

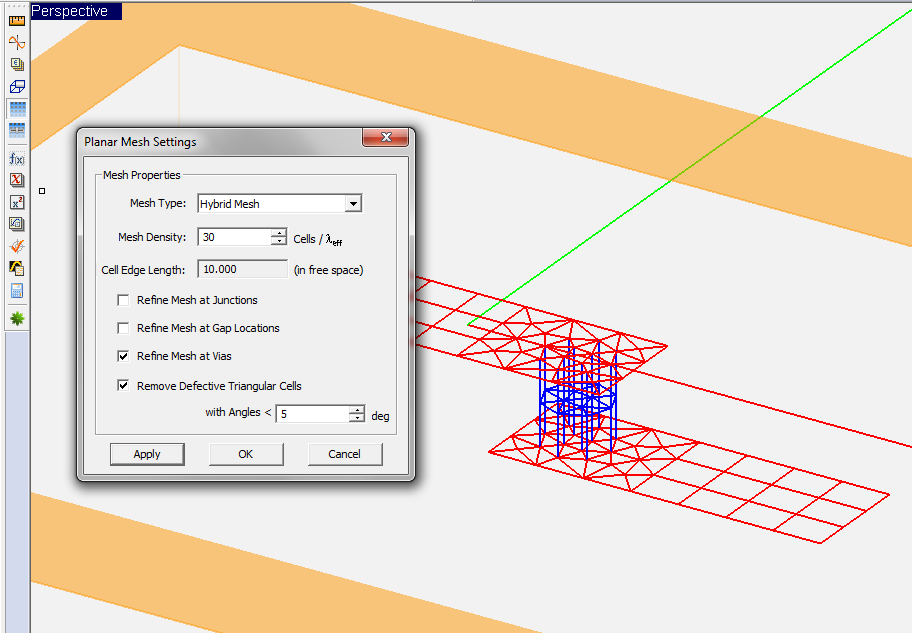

- 3.4 Planar Mesh Density

- 3.5 Customizing A Planar Mesh

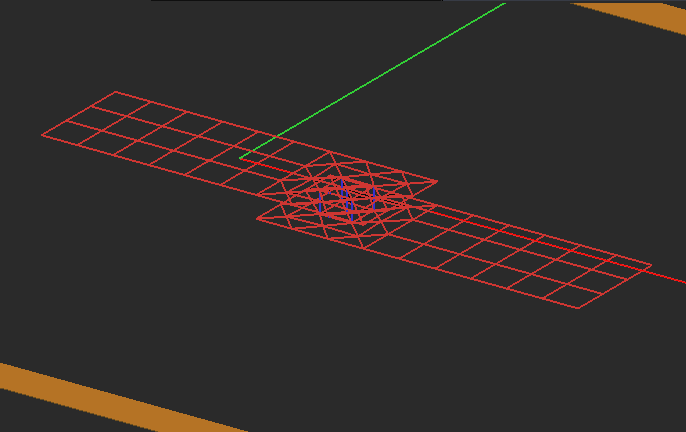

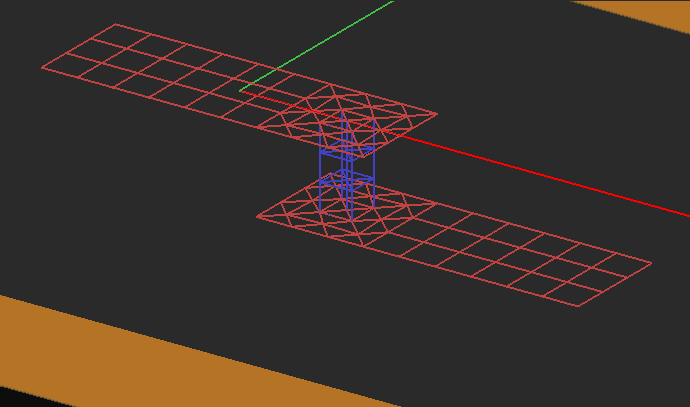

- 3.6 Mesh Of Connected Trace Objects

- 3.7 Mesh of Embedded Objects

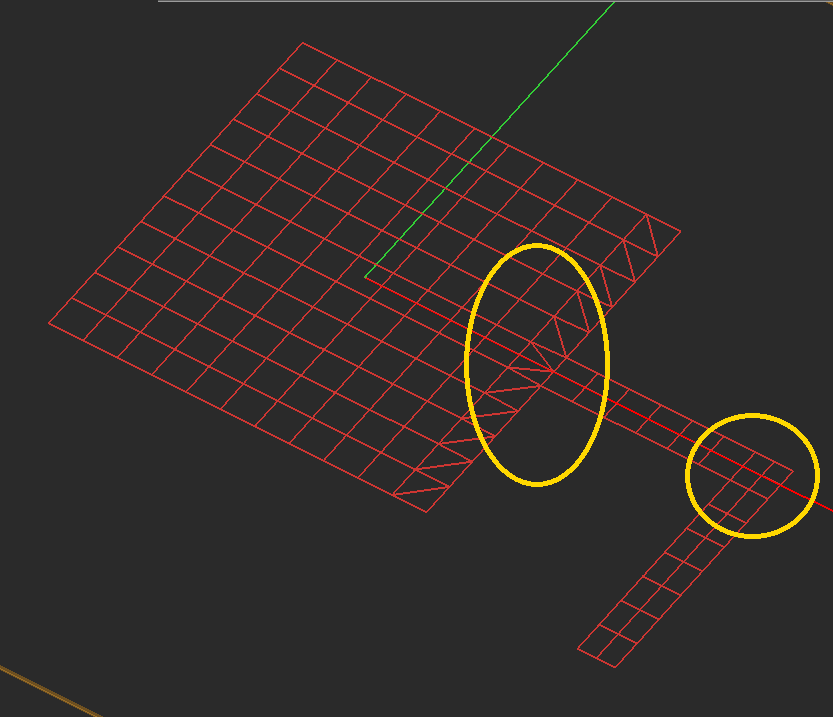

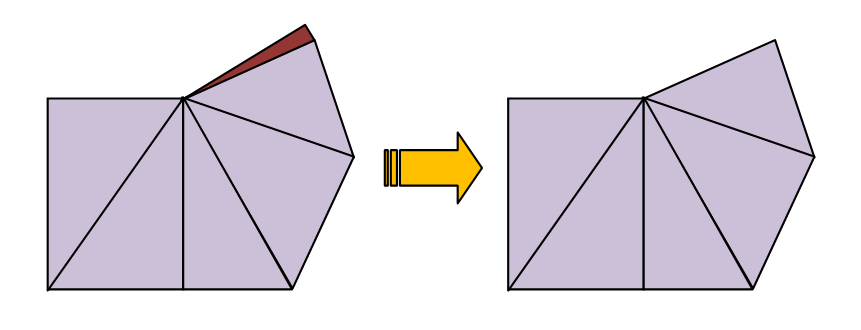

- 3.8 Refining Mesh At Discontinuities

- 3.9 Checking Mesh Integrity

- 3.10 Locking Mesh Of Object Groups

- 3.11 Local Mesh Control Using Polymesh Objects

- 4 Excitation Sources

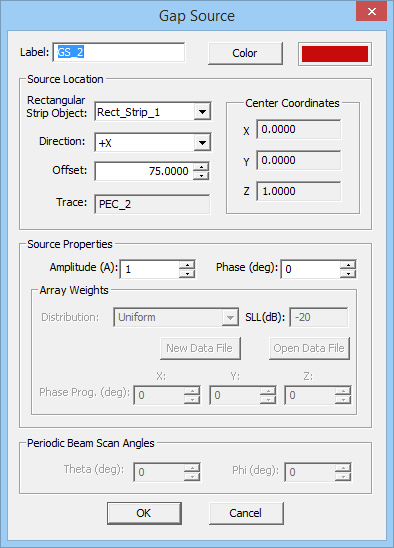

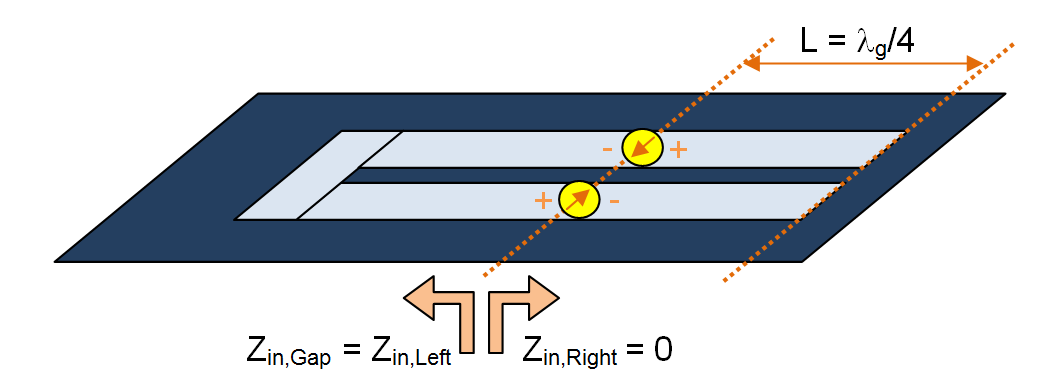

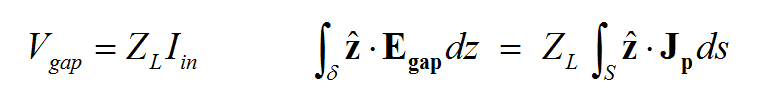

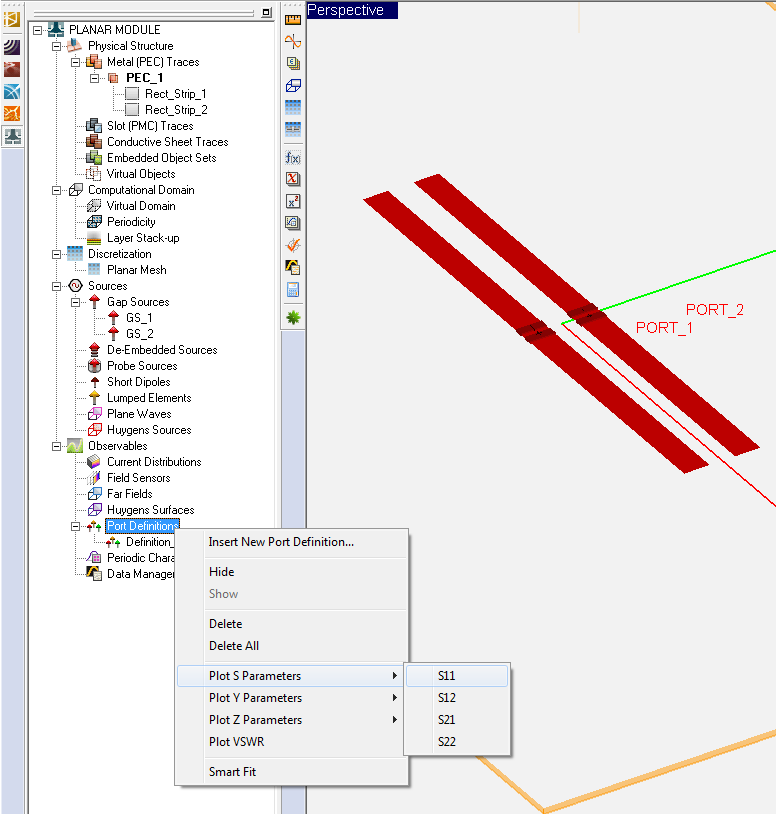

- 4.1 Gap Sources

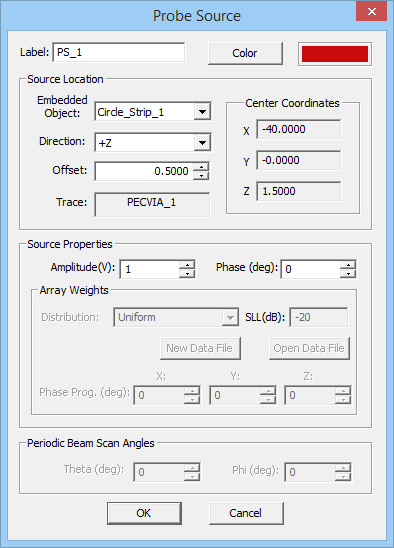

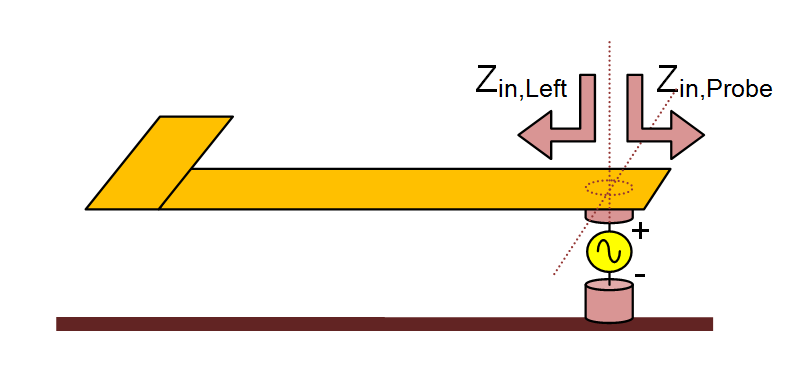

- 4.2 Probe Sources

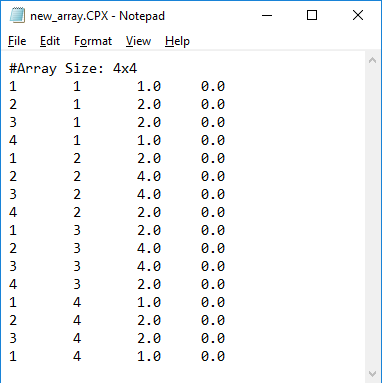

- 4.3 Defining Source Arrays

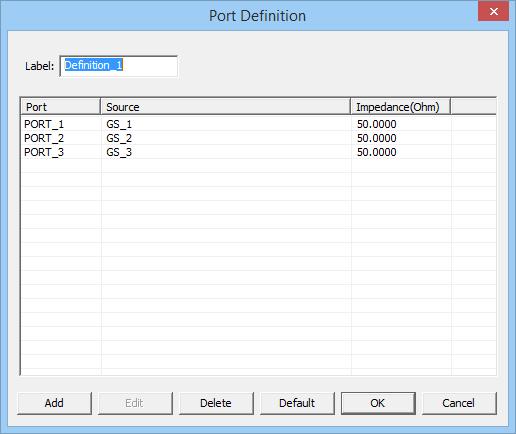

- 4.4 Defining Ports

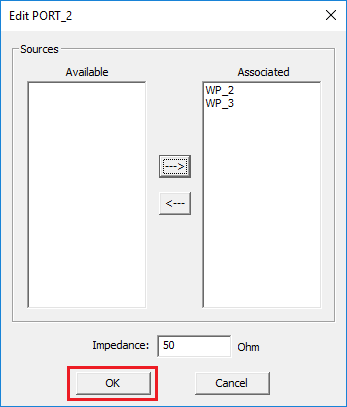

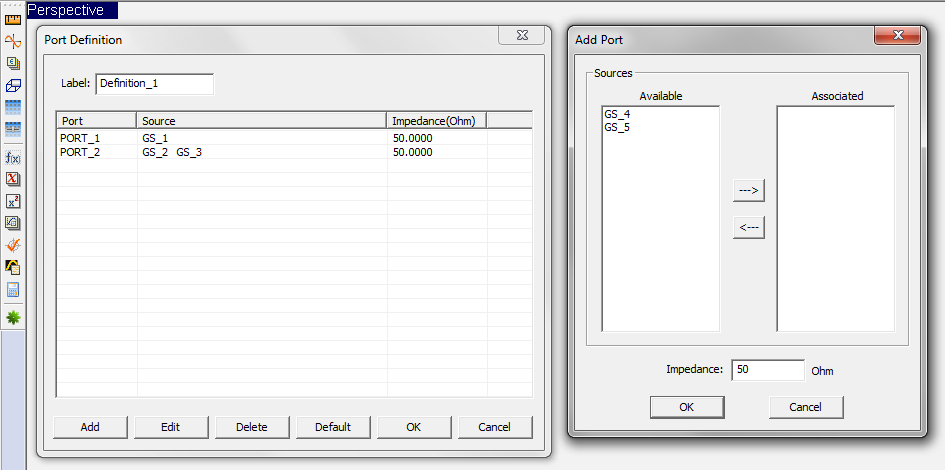

- 4.5 Modeling Coupled Ports

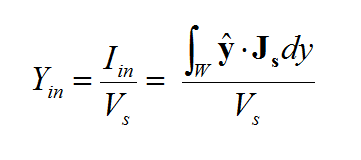

- 4.6 Calculating Port Characteristics At Gap Discontinuities

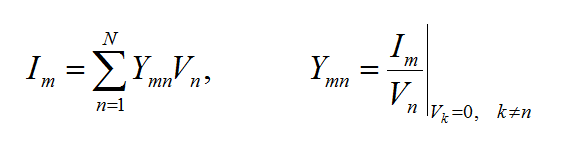

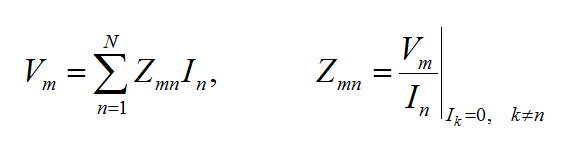

- 4.7 Exciting Multiport Structures Using Linear Superposition

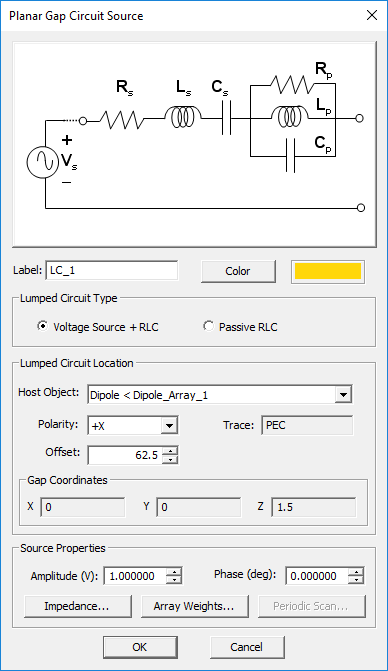

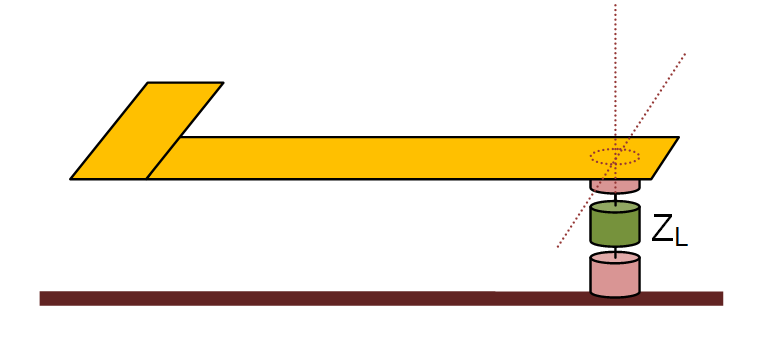

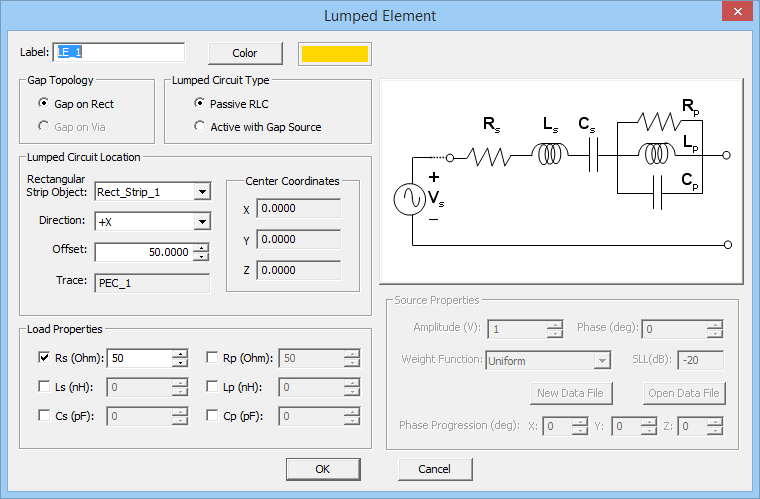

- 4.8 Modeling Lumped Elements In Planar MoM

- 4.9 Defining Lumped Circuits

- 4.10 Calculating Scattering Parameters Using Prony's Method

- 4.11 De-Embedded Sources

- 4.12 Using the Line Calculator

- 4.13 Short Dipole Sources

- 4.14 Plane Wave Sources

- 5 Running Planar MoM Simulations

- 5.1 Planar Module's Simulation Modes

- 5.2 Running A Planar MoM Analysis

- 5.3 Stages Of A Planar MoM Analysis

- 5.4 Setting Numerical Parameters

- 5.5 Planar Module's Linear System Solvers

- 5.6 Visualizing Current Distributions

- 5.7 Computing The Near Fields

- 5.8 Visualizing The Near Fields

- 5.9 Computing The Far Fields

- 5.10 Visualizing The Far Fields

- 5.11 Radar Cross Section of Planar Structures

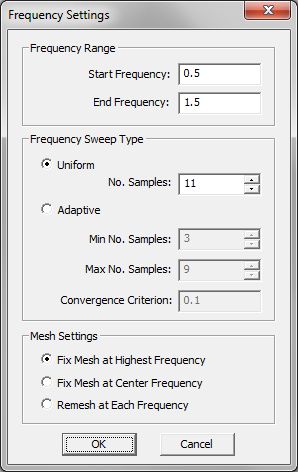

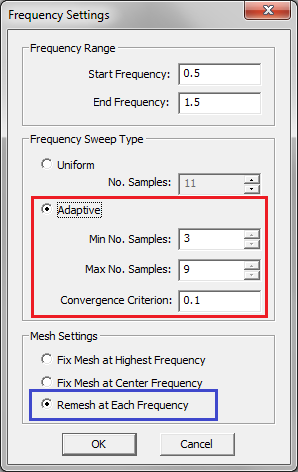

- 5.12 Running a Frequency Sweep

- 5.13 Adaptive Frequency Sweep

- 5.14 Examining Port Characteristics

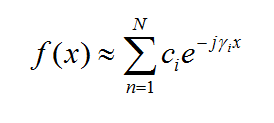

- 5.15 Rational Interpolation Of Scattering Parameters

- 5.16 Planar Module's Output Simulation Data

- 5.17 Standard vs. Custom Output

- 5.18 Viewing & Visualizing Various Output Data Types

- 5.19 Running a Parametric Sweep

- 5.20 Optimizing Planar Structures

- 6 Periodic Planar Structures & Antenna Arrays

- 6.1 Finite Arrays vs. Infinite Periodic Structures

- 6.2 Modeling Finite Antenna Arrays

- 6.3 Defining A Periodic Domain

- 6.4 Regular vs. Generalized Periodic Lattices

- 6.5 Interconnectivity Among Unit Cells

- 6.6 Periodic MoM Simulation

- 6.7 Modeling Periodic Phased Arrays

- 6.8 Exciting Periodic Structures Using Plane Waves

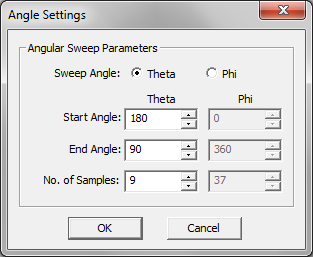

- 6.9 Characterizing Periodic Surfaces Using Angular Sweeps

- 6.10 Modeling Periodic Structures Using Adaptive Frequency Sweeps

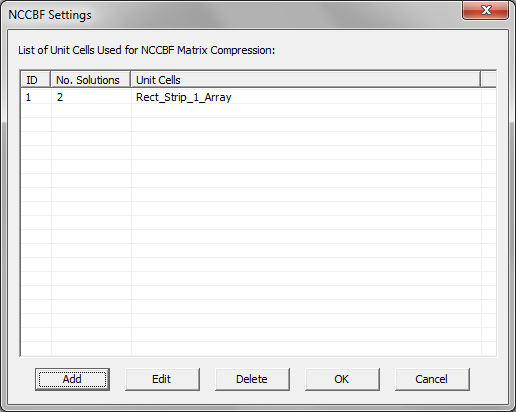

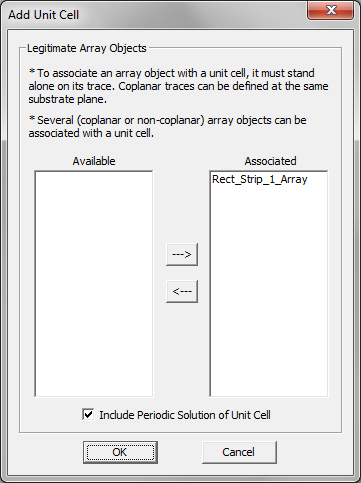

- 6.11 Modeling Finite-Sized Periodic Arrays Using NCCBF Technique

- 6.12 Running a NCCBF Simulation

- 6.13 Symmetries, Array Objects & Composite Arrays

A Planar Method Of Moments Primer

Multilayer Green’s Functions

The Green’s functions are the solutions of boundary value problems when they are excited by an elementary source. This is usually assumed to be an infinitesimally small vectorial point source. In order for Green’s functions to be computationally useful, they must have analytical closed forms like a mathematical expression, or one should be able to compute them using a recursive process. It turns out that only very few boundary value problems have closed-form Green’s functions. Planar layered structures with laterally infinite extents are one of those few cases, which can be represented by recursive dyadic Green's functions.

In general, a structure may support both electric (J) and magnetic (M) currents. The total electric (E) and magnetic (H) fields can be expressed in terms of the electric and magnetic currents in the following way:

- [math]E = E^{inc} + \iiint\limits_V \overline{\overline{G_{EJ}}}(r|r') \cdot J(r') \, dv' + \iiint\limits_V \overline{\overline{G_{EM}}}(r|r') \cdot M(r') \, dv'[/math]

- [math]H = H^{inc} + \iiint\limits_V \overline{\overline{G_{HJ}}}(r|r') \cdot J(r') \, dv' + \iiint\limits_V \overline{\overline{G_{HM}}}(r|r') \cdot M(r') \, dv'[/math]

where GEJ, GEM, GHJ, GHM are the dyadic Green’s functions for the electric and magnetic currents due to electric and magnetic current source, respectively, and Ei and Hi are the incident or impressed electric and magnetic fields, respectively. In these equations, r is the position vector of the observation point and r' is the position vector of the source point. V is the volume that contains all the sources and the volume integration is performed with respect to the primed coordinates. The incident or impressed fields provide the excitation of the structure. They may come from an incident plane wave or a gap source on a microstrip line, a short dipole, etc. The complexity of the Green’s functions depends on what is considered as the background structure. If you remove all the unknown currents from the structure, you are left with the background structure.

Planar Integral Equations

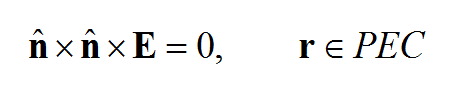

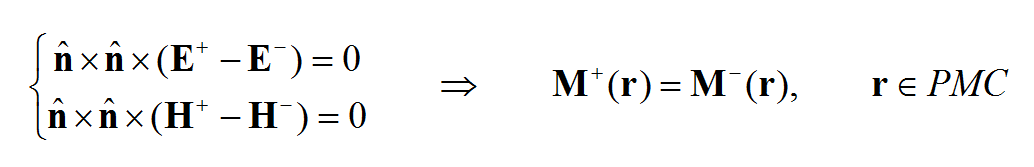

To derive a system of integral equations, we enforce the boundary conditions on the integral definitions of the E and H fields as follows:

where LE is the boundary value operator for the electric field and LH is the boundary value operator for the magnetic field. For example, LE may require that the tangential components of the Efield vanish on perfect conductors:

Or LE and LH may require that the tangential components of the E and H fields be continuous across an aperture in a perfect ground plane:

Given the fact that the dyadic Green’s functions and the incident or impressed fields are all known, one can solve the above system of integral equations to find the unknown currents J and M.

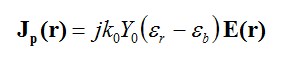

In EM.CUBE's Planar module, magnetic currents are always surface current with units of V/m. Electric currents, however, can be surface currents with units of A/m as in the case of metallic traces like microstrip lines, or they can be volume currents with units of A/m2 as in the case of perfectly conducting vias. Dielectric inserts are modeled as volume polarization currents that are related to the electric field E in the following manner:

where k0 is the free space propagation constant, Y0=1/Z0 =1/(120p) is the free space intrinsic admittance, er is the permittivity of the dielectric insert, and eb is the permittivity of its background layer. In a 2.5-D formulation, it is assumed that the volume currents have only a vertical component along the Z direction, and their circumferential components are negligible.

Numerical Solution Of Integral Equations

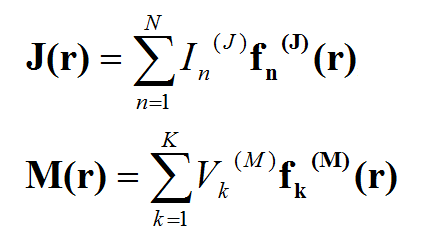

The planar integral equations derived earlier can be solved numerically by discretizing the unknown currents using a proper meshing scheme. The original functional equations are reduced to discretized linear algebraic equations over elementary cells. The unknown quantities are found by solving this system of linear equations, and many other parameters can be computed thereafter. This method of numerical solution of integral equations is known as the Method of Moments (MoM). In this method, the unknown electric and magnetic currents are represented by expansions of basis functions as follows:

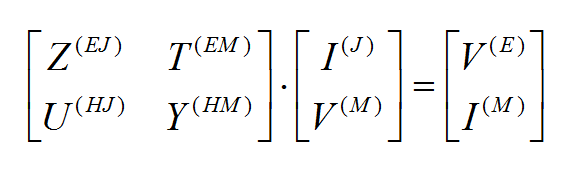

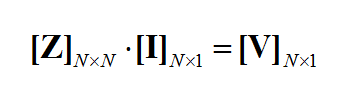

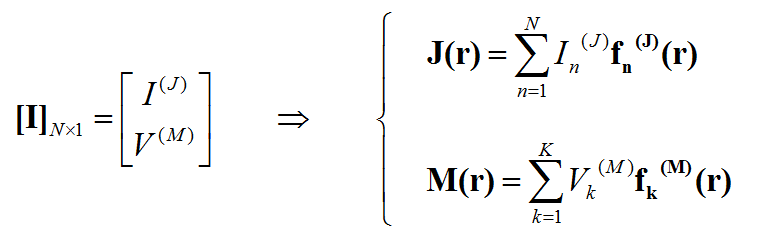

where fn(J) and fk(M) are the generalized vector basis functions for the expansion of electric and magnetic currents, respectively, and In(J) and Vk(M) are the unknown amplitudes of these basis functions, which have to be determined. Substituting these expansions into the integral equations generates a set of discretized integral equations, which can further be converted to a system of linear algebraic equations. This is accomplished by testing the discretized integral equations using the a set of test functions. In the method of moments, the Galerkin technique is typically used, which chooses the expansion basis functions as test functions. This leads to the following linear system:

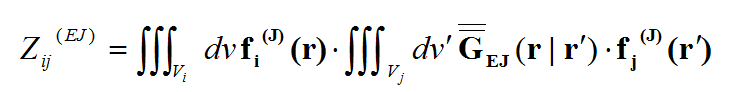

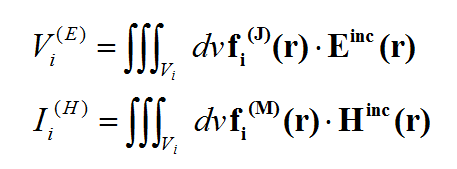

where

and

Similar expressions can be derived for the T(EM), U(HJ) and Y(HM)elements of the MoM matrix.

Discretization Of Electric & Magnetic Currents

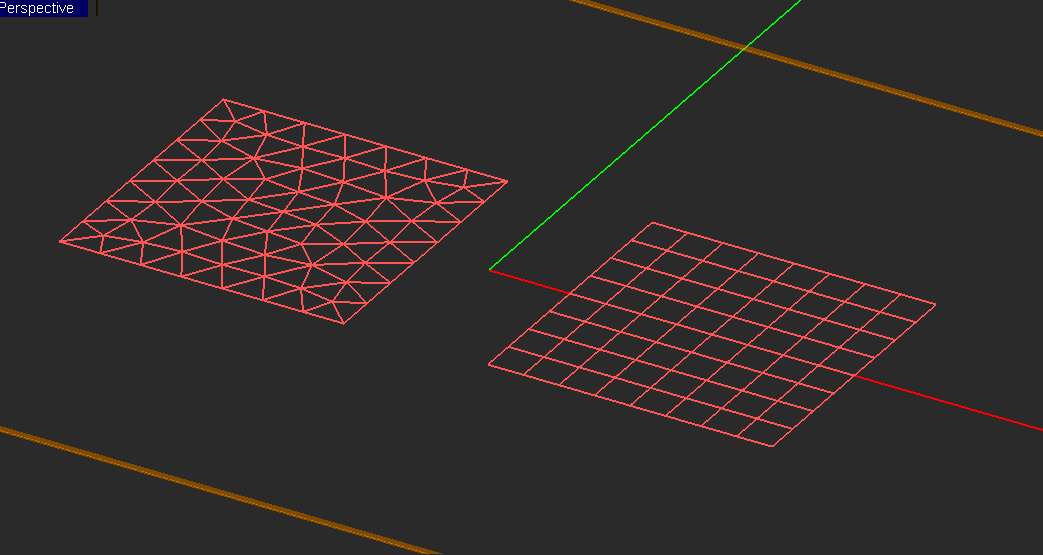

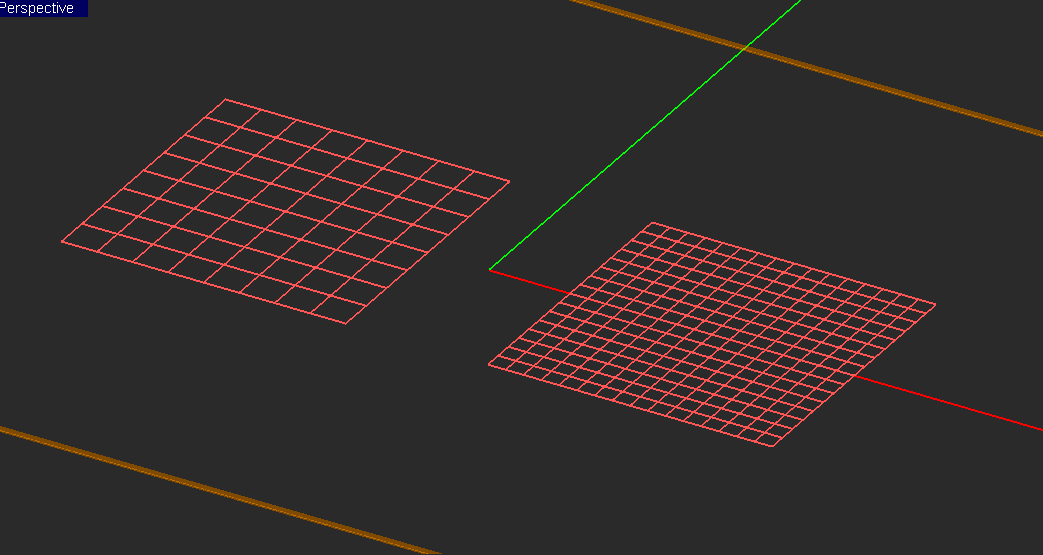

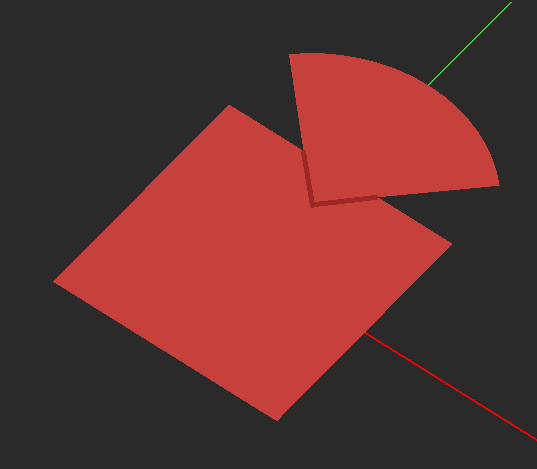

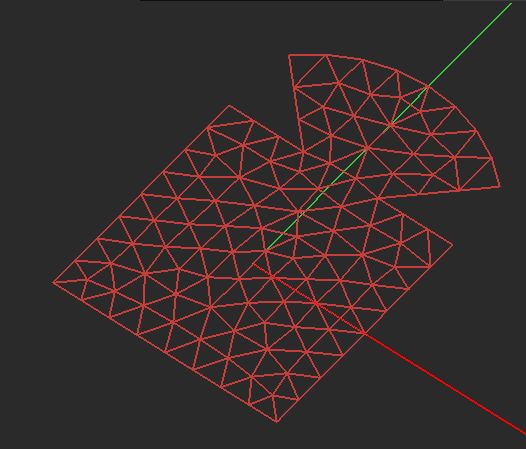

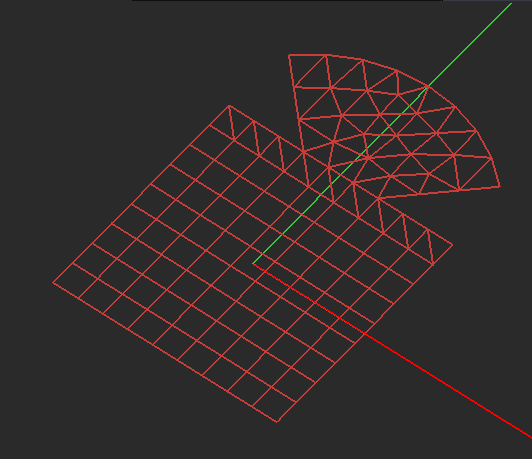

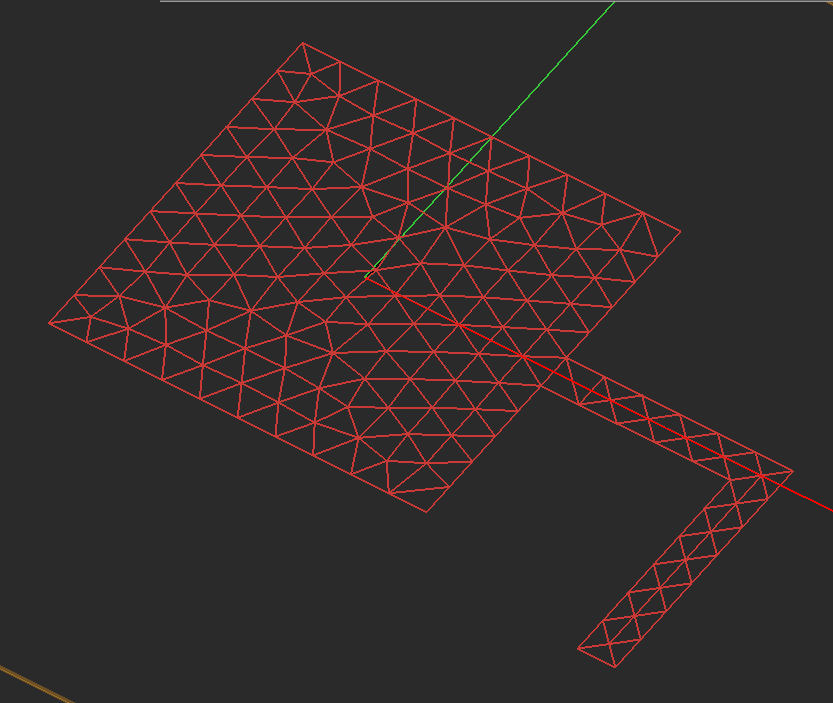

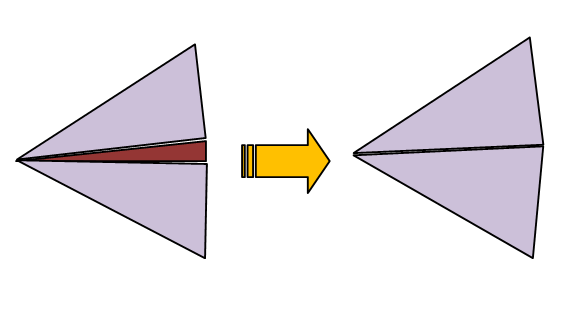

The right choice of the basis functions to represent the elementary currents is very important. It will determine the accuracy and computational efficiency of the resulting numerical solution. Rooftop basis functions are one of the most popular types of basis functions used in a variety of MoM formulations. The surface currents (whether electric or magnetic) are discretized using 2D rooftop basis functions shown in the figure below:

Figure 1: Rooftop or RWG basis functions built over two rectangular, triangular or mixed cells.

The rooftop basis functions are defined over two adjacent cells with a common edge of length. If the two cells are triangular, then the so-called RWG functions are obtained. It is also possible to define rooftop functions over two adjacent rectangular cells or two adjacent rectangular and triangular cells with a common edge. On a rectangular cell, the function is defined as having a (descending or ascending) linear profile in one direction and a constant profile in the other perpendicular direction.

The volume polarization currents in 2.5-D MoM have a vertical direction along the Z-axis. These are discretized using prismatic basis functions that have either a rectangular or triangular base with a constant profile along the Z-axis.

Figure 2: Prismatic basis functions built over single triangular and rectangular cells.

Anatomy Of A Planar Structure

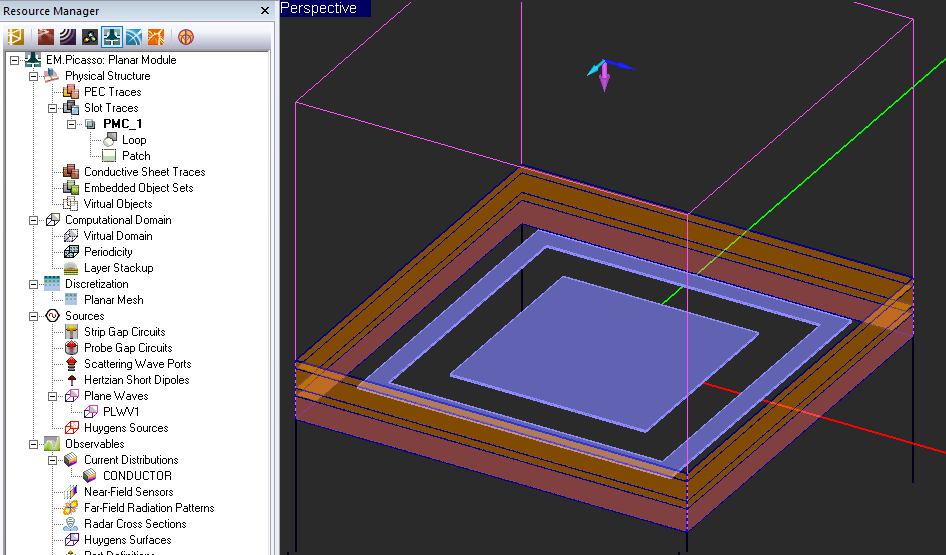

EM.Cube’s Planar Module is intended for constructing and modeling planar layered structures. By a planar structure we mean one that contains a background substrate of laterally infinite extents, made up of one or more material layers all stacked up vertically along the Z axis. Objects of finite size are then interspersed among these substrate layers. This is somehow different than EM.Cube's other computational modules, which are geared for handling arbitrary 3D structures.

In Planar Module, the background structure, called "Layer Stack-up", may involve one or more material layers of infinite extents along the X and Y axes but of finite thickness along the Z axis. When you start a new project, the background structure has a single vacuum layer. The layer stack-up is always terminated from the top and bottom by two infinite half-spaces. The terminating half-spaces might be the free space, or a perfect conductor (PEC ground), or any material medium. Most planar structures used in RF and microwave applications such as microstrip-based components have a PEC ground at their bottom. EM.Cube's default stack-up has a vacuum top half-space and a PEC bottom half-space. Some structures like stripline components require two bounding PEC grounds at both top and bottom.

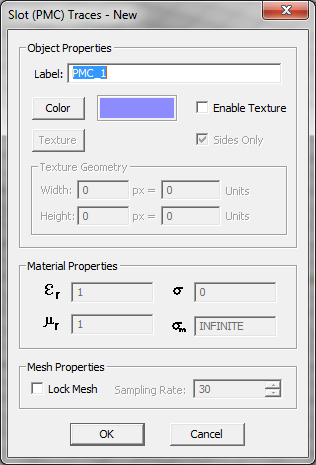

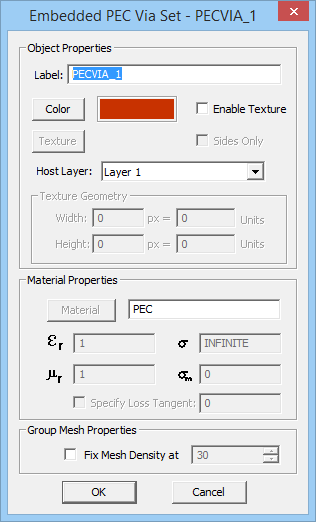

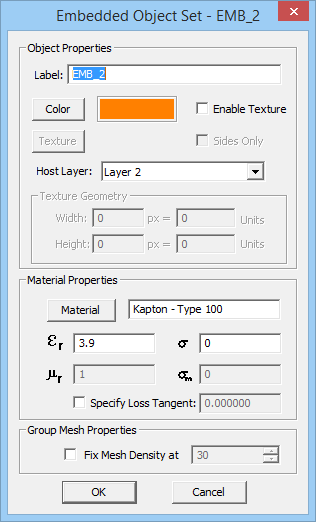

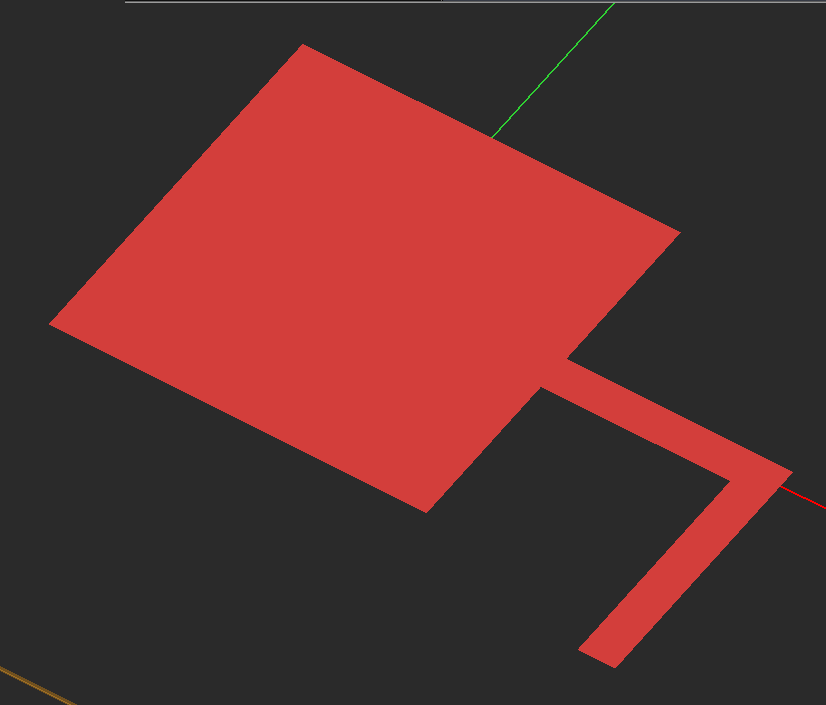

The finite-sized objects of a planar structure may include metal traces, slots and apertures, vertical vias and interconnects, or dielectric inserts including air voids inside the substrate layers. Metal traces are modeled as electric surface currents. These are planar surface objects, always parallel to the XY plane, that are defined on metal (PEC) traces and placed at the boundary (interface) plane between two substrate layers. Slots and apertures are modeled as magnetic surface currents on the surface of an infinite PEC plane and provide electromagnetic coupling between its top and bottom sides. These, too, are constructed using planar surface objects, always parallel to the XY plane, that are defined on slot (PMC) traces and placed at the boundary (interface) plane between two substrate layers. EM.Cube's Planar Module also allows prismatic objects that can be modeled by electric volume currents. These include vertical vias and dielectric inserts, and are called embedded object sets. Planar module does not allow construction of 3D CAD objects. Instead, you draw the cross section of prismatic objects as planar surface objects parallel to the XY plane. EM.Cube then automatically extrudes these cross sections and constructs and displays 3D prisms over them. The prisms extend all the way across the thickness of the host substrate layer.

Defining Layer Stack-Up

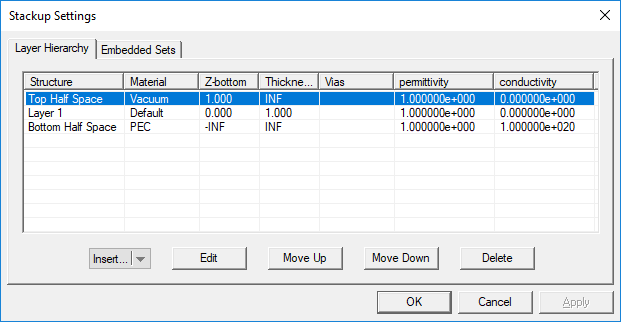

When you start a new project in EM.Cube’s Planar Module, there is always a default background structure that consists of a finite vacuum layer sandwiched between a vacuum top half-space and a PEC bottom half-space. Every time you enter the Planar module, the Stack-up Settings Dialog opens up. This is where you define the entire background structure. Once you close this dialog, you can open it again by right clicking the Layer Stack-up item in the Computational Domain section of the Navigation Tree and selecting Layer Stack-up Settings... from the contextual menu. Or alternatively, you can select the menu item Simulate > Computational Domain > Layer Stack-up Settings...

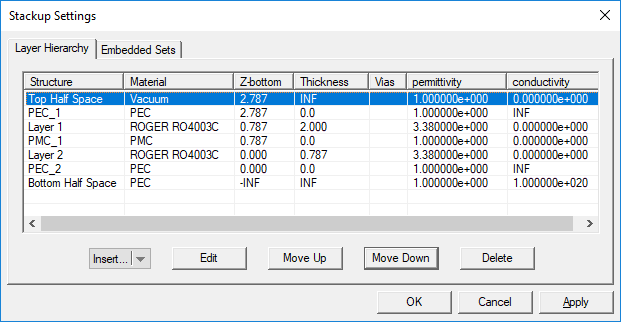

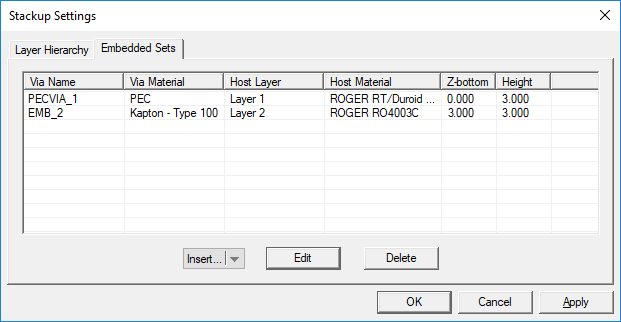

The Stack-up Settings dialog has two tabs: Layer Hierarchy and Embedded Sets. The Layer Hierarchy tab has a table that shows all the background layers in hierarchical order from the top half-space to the bottom half-space. It also lists the material label of each layer, Z-coordinate of the bottom of each layer, its thickness (in project units) and material properties: permittivity (er), permeability (µr), electric conductivity (s) and magnetic conductivity (sm). There is also a column that lists the names of embedded object sets inside each substrate layer, if any.

You can add new layers to your project's stack-up or delete its layers, or move layers up or down and thus change the layer hierarchy. To add a new background layer, click the arrow symbol on the Insert...button at the bottom of the dialog and select Substrate Layer from the button's dropdown list. A new dialog opens up where you can enter a label for the new layer and values for its material properties and thickness in project units.

You can delete a layer by selecting its row in the table and clicking the Delete button. To move a layer up and down, click on its row to select and highlight it. Then click either the Move Up or Move Down buttons consecutively to move the selected layer to the desired location in the stack-up. Note that you cannot delete or move the top or bottom half-spaces.

Figure 1: Planar Module's Layer Stack-up Settings dialog.

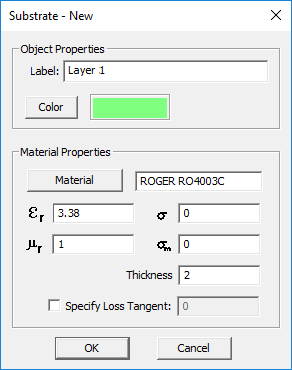

Editing Substrate Layers

After creating a substrate layer, you can always edit its properties in the Layer Stack-up Settings dialog. Click on any layer's row in the table to select and highlight it and then click the Edit button. The substrate layer dialog opens up, where you can change the layer's label and assigned color. In the material properties section of the dialog, you can change the name of the material and its properties: permittivity (er), permeability (µr), electric conductivity (s) and magnetic conductivity (sm). To define electrical losses, you can either assign a value for electric conductivity (s), or alternatively, define a loss tangent for the material. In the latter case, check the box labeled "Specify Loss Tangent" and enter a value for it. In this case, the electric conductivity field becomes greyed out and reflects the corresponding s value at the center frequency of the project.

You can also set the thickness of the substrate layer in the project units. Note that you cannot change the thickness of the top and bottom half-spaces. You can only change their material properties.

Figure 1: Planar Module's Substrate Layer dialog.

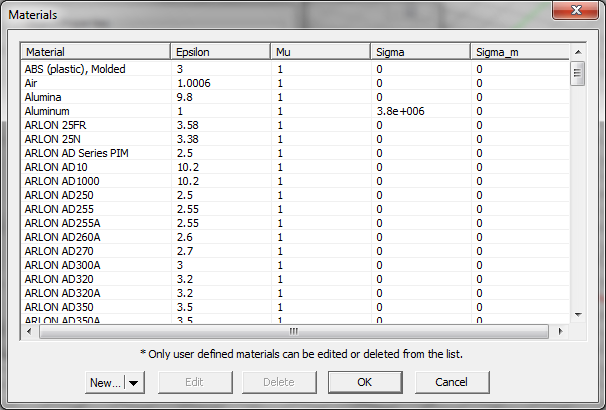

You can also use EM.Cube's Material List to define the material properties of a substrate layer. In the Substrate Layer Dialog, click the Material button to open the Material List. In the Material List Dialog, pick any material or type the first letter of a material to highlight it. Then click the OK button or simply hit the Enter key of your keyboard to close the list and return to the substrate layer dialog.

Figure 2: EM.Cube's Materials dialog.

Planar Object Types

EM.Cube’s Planar Module groups objects by their material and electromagnetic properties. Each object group shares the same color and same position in the layer stack-up. All the planar objects belonging to the same trace are located on the same substrate layer boundary. All the prismatic objects belonging to the same embedded set lie inside the same substrate layer and have the same material composition. Theoretically speaking, all the objects belonging to a group are governed by the same boundary conditions. EM.Cube’s Planar Module currently provides the following types of objects for building a planar layered structure:

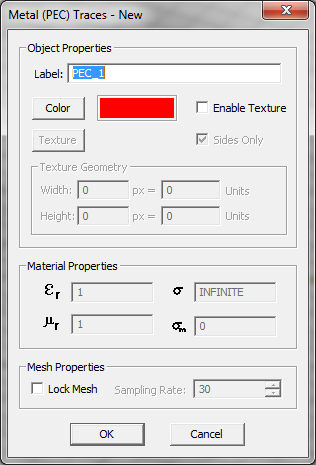

- Perfect Electric Conductor (PEC) Traces: These represent infinitesimally thin metallic objects that are deposited or metallized on or between substrate layers. PEC objects are modeled by surface electric currents that satisfy the PEC boundary condition.

- Perfect Magnetic Conductor (PMC) Traces: These are used to model slots and apertures in infinite PEC ground planes. PMC objects are always assumed to lie on an infinite horizontal PEC ground plane with zero thickness. They are modeled by surface magnetic currents, enforcing the continuity of tangential fields across the slots or apertures.

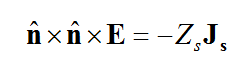

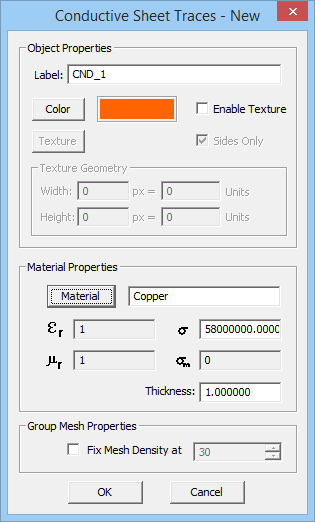

- Conductive Sheet Traces: These represent imperfect metals. They have a finite conductivity and a very small thickness. A surface impedance boundary condition is enforced on the surface of such traces.

- PEC Via Sets: These are metallic objects such as shorting pins, interconnect vias, plated-through holes, etc. that are grouped together as prismatic object sets. The embedded objects are modeled as vertical volume conduction currents.

- Embedded Dielectric Sets: These are prismatic dielectric objects inserted inside a substrate layer. You can define a finite permittivity and conductivity for such objects, but their height is always the same as the height of their host layer. The embedded dielectric objects are modeled as vertical volume polarization currents.

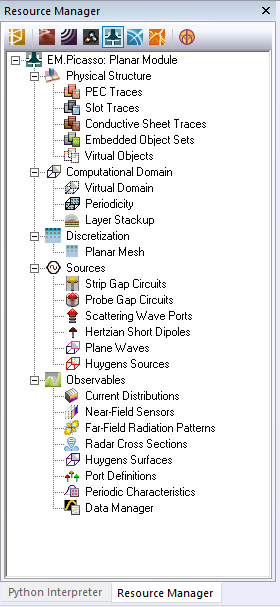

Figure 1: Planar Module's Navigation Tree.

Defining Traces & Object Sets

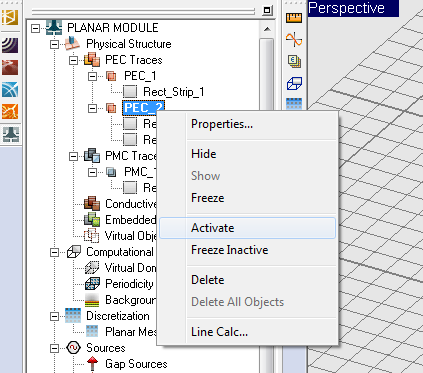

When you start a new project in Planar Module, the project workspace looks empty, and there are no finite objects in it. However, a default background structure is always assumed to exist by default. Objects are defined as part of traces or embedded sets. Once defined, you can see a list of project objects in the Physical Structure section of the Navigation Tree. Traces and object sets can be defined either from Layer Stack-up Settings dialog or from the Navigation Tree.

In the Layer Stack-up Settings dialog, you can add a new trace to the stack-up by clicking the arrow symbol on the Insert button of the dialog. You have to choose from Metal (PEC), Slot (PMC) or Conductive Sheet options. A respective dialog opens up, where you can enter a label and assign a color other than default ones. Once a new trace is defined, it is added, by default, to the top of the stack-up table underneath the top half-space. From here, you can move the trace down to the desired location on the layer hierarchy.

Figure 1: Planar Module's Stack-up Settings dialog.

Every time you define a new trace, it is also added under the respective category in the Navigation Tree. Alternatively, you can define a new trace from the Navigation Tree by right clicking on one of the trace type names and selecting Insert New PEC Trace...or Insert New PMC Trace...or Insert New Conductive Sheet Trace...A respective dialog opens up for setting the trace properties. Once you close this dialog, it takes you directly to the Layer Stack-up Settings dialog so that you can set the right position of the trace on the stack-up.

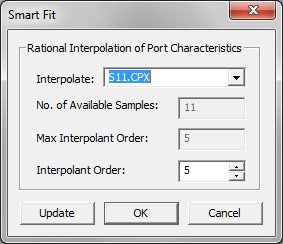

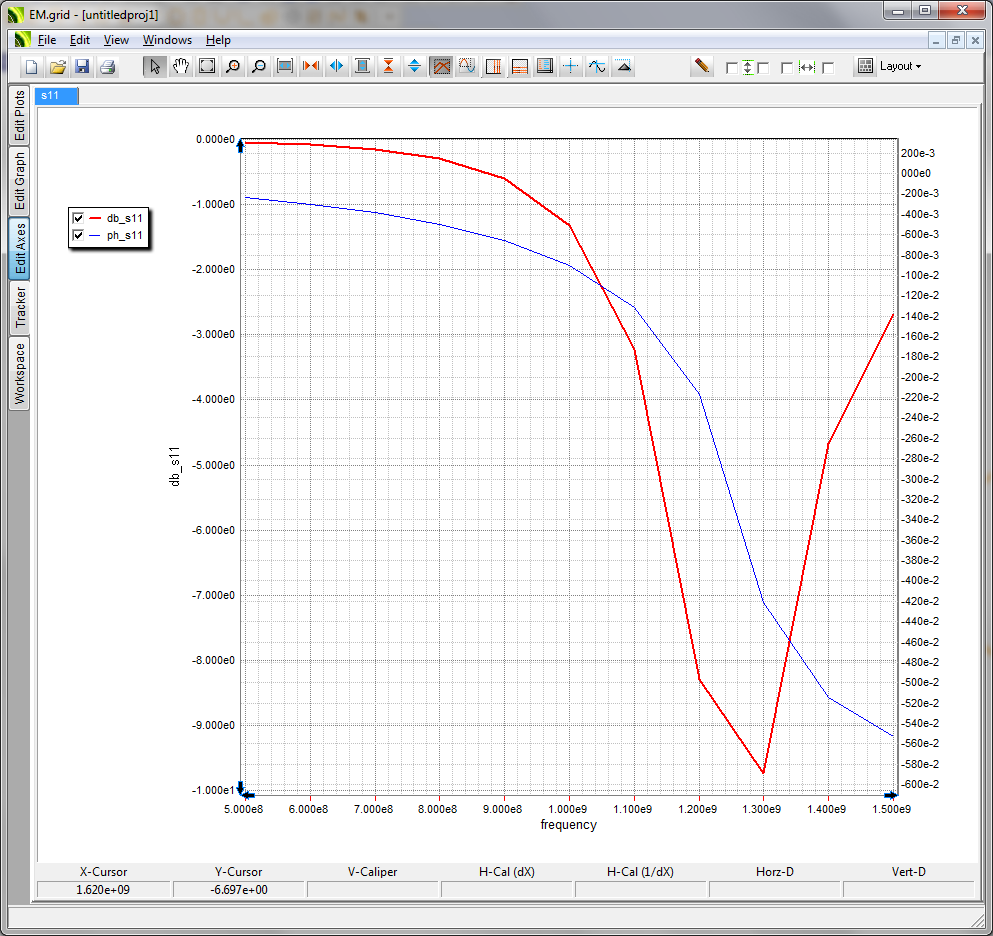

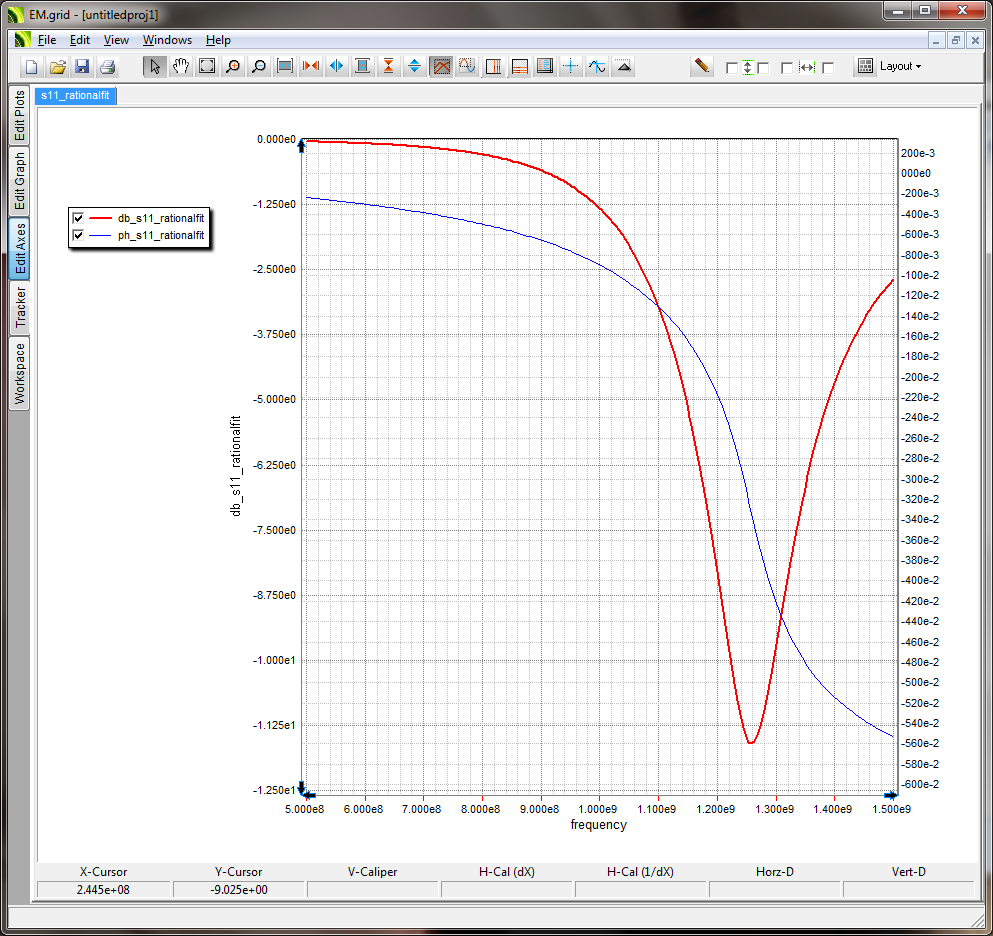

Drawing Planar Objects